You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front shock absorbers removal

- Thread starter SixBanger

- Start date

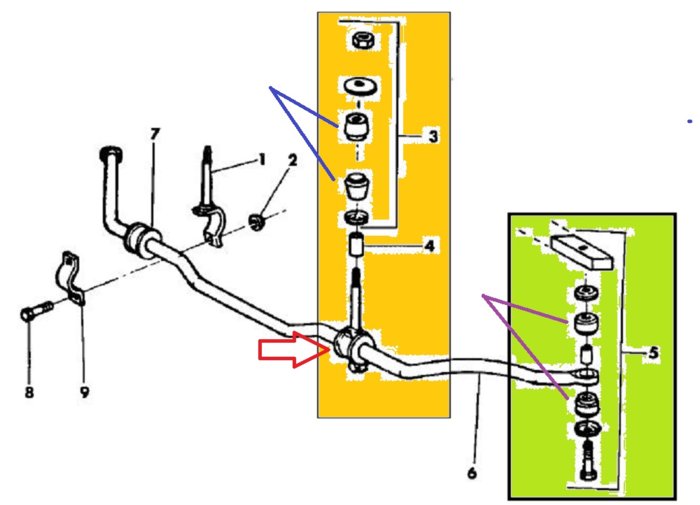

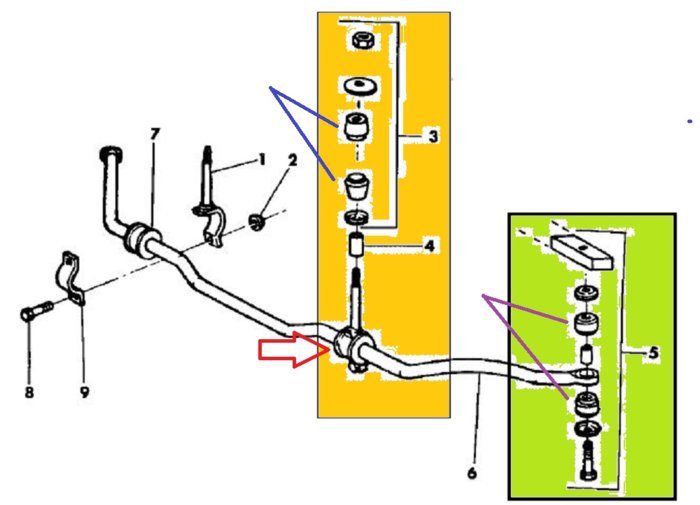

To make sure everyone is on same train of thought, the end link bushings (green box) are ones close to wheel. The frame bushings generally attach to frame (or K-frame), but our design has a link between the bar and frame (orange box).

There is a total of 10 front sway bar bushings (2 end links (purple lines), 2 link to K-frame (blue lines) and 1 center sway bar (red arrow), per side).

The front end-link bushings are all the same.

The center link to frame bushings are all the same (but different from end link bushings, if I recall correctly).

The sway bar (center) bushings come in different diameters (small, medium and large) – based off the three-different sized front sway bars – Normal, heavy duty and police (police are also referred as Extra Duty). I do not recall seeing a factory heavy-duty bar (HD), before (that I recall).

The regular bars are about 1” inch in diameter (25.4mm).

The police/ED bar is 1-1/8” in diameter (28.6mm).

Again, I have no idea on what the HD bar diameter is (don’t recall ever seeing one).

Aftermarket has come out with different bar diameters – so that might be part of the difference.

The bar bushings are different shaped than most replacement bar bushings are – so if possible take a (old) bushing with you, before buying (to match up).

The center links are the weak link (behind the rubber bushings wearing out) of the front sway bar. I have replaced a bunch of those links before (I doubt the owner even knows they are broken. The police/ED version are a tad bit stronger – but not strong enough.

The center links from Firm Feel are a huge upgrade – but as far as I know, are only available as part of their front sway bar kit. http://www.firmfeel.com/fmj_body_mopar_front_sway_bar.html

Matter of fact, anytime I’m at a pull-a-part and find an FMJ (or newer B, C or R-body), I try to grab any good links. Here lately, almost all the cars I have found, at least one link is broken. Currently I have 2 spares – but holding onto them until I can obtain the Firm Feel bar kits (at $400 each (US), times 4, in my case), in case I have another one break on me.

If I recall correctly, the rear police sway bar is ¾” diameter.

Note: I do highly recommend replacing any rubber sway bar bushing with urethane - for any car, not just for an FMJ vehicle (unless you are restoring one back to factory specs).

They cost a bit more but are well worth the price difference. Urethane sway bar bushings will not add any harshness to your ride and makes the sway bar work harder (the sway bar comes into effect a lot faster, sense normally you are waiting for rubber to compresses, first).

If I have any say in the matter, I will not install any rubber sway bar bushings.

BudW

Edit: the police/ED center links are made differently from the normal/HD versions. Also, the outer diameter of the bar bushing is smaller for police/ED bars. So not only is the inner diameter different but outer diameter is also different – which is why I recommend taking an existing bushing with you to parts store – to match up with.

There is a total of 10 front sway bar bushings (2 end links (purple lines), 2 link to K-frame (blue lines) and 1 center sway bar (red arrow), per side).

The front end-link bushings are all the same.

The center link to frame bushings are all the same (but different from end link bushings, if I recall correctly).

The sway bar (center) bushings come in different diameters (small, medium and large) – based off the three-different sized front sway bars – Normal, heavy duty and police (police are also referred as Extra Duty). I do not recall seeing a factory heavy-duty bar (HD), before (that I recall).

The regular bars are about 1” inch in diameter (25.4mm).

The police/ED bar is 1-1/8” in diameter (28.6mm).

Again, I have no idea on what the HD bar diameter is (don’t recall ever seeing one).

Aftermarket has come out with different bar diameters – so that might be part of the difference.

The bar bushings are different shaped than most replacement bar bushings are – so if possible take a (old) bushing with you, before buying (to match up).

The center links are the weak link (behind the rubber bushings wearing out) of the front sway bar. I have replaced a bunch of those links before (I doubt the owner even knows they are broken. The police/ED version are a tad bit stronger – but not strong enough.

The center links from Firm Feel are a huge upgrade – but as far as I know, are only available as part of their front sway bar kit. http://www.firmfeel.com/fmj_body_mopar_front_sway_bar.html

Matter of fact, anytime I’m at a pull-a-part and find an FMJ (or newer B, C or R-body), I try to grab any good links. Here lately, almost all the cars I have found, at least one link is broken. Currently I have 2 spares – but holding onto them until I can obtain the Firm Feel bar kits (at $400 each (US), times 4, in my case), in case I have another one break on me.

If I recall correctly, the rear police sway bar is ¾” diameter.

Note: I do highly recommend replacing any rubber sway bar bushing with urethane - for any car, not just for an FMJ vehicle (unless you are restoring one back to factory specs).

They cost a bit more but are well worth the price difference. Urethane sway bar bushings will not add any harshness to your ride and makes the sway bar work harder (the sway bar comes into effect a lot faster, sense normally you are waiting for rubber to compresses, first).

If I have any say in the matter, I will not install any rubber sway bar bushings.

BudW

Edit: the police/ED center links are made differently from the normal/HD versions. Also, the outer diameter of the bar bushing is smaller for police/ED bars. So not only is the inner diameter different but outer diameter is also different – which is why I recommend taking an existing bushing with you to parts store – to match up with.

Last edited:

89.Fifth

Well-Known Member

The police sway bar is indeed 3/4" and let me tell you... it rides ROUGH. I think I might remove it altogether.

SixBanger

Well-Known Member

Great thanks guys for the info and links. I don't have much experience with car suspension etc. So that extra info about the different setups and inner and outer bushings are welcome.

MiradaMegacab thanks for that link. That 1 inch front sway bar bushings kit is what I am looking for. One review of that kit shows the 'symptoms' of the poor handling of the car.

Now the car has some nose diving and tire squealing in corners and roundabouts.

Especially when I send to the left. It does not happen occasionally.

I doubt if this is the suspension? If the car is cold, the belt of the power steering pump will slip. The oil level remains good, and I have tightened the string.

Maybe I mix up two problems.

MiradaMegacab thanks for that link. That 1 inch front sway bar bushings kit is what I am looking for. One review of that kit shows the 'symptoms' of the poor handling of the car.

Now the car has some nose diving and tire squealing in corners and roundabouts.

Especially when I send to the left. It does not happen occasionally.

I doubt if this is the suspension? If the car is cold, the belt of the power steering pump will slip. The oil level remains good, and I have tightened the string.

Maybe I mix up two problems.

The police sway bar is indeed 3/4" and let me tell you... it rides ROUGH. I think I might remove it altogether.

A sway bar doesn't make your car ride rough. Tires, springs, shocks or a combination thereof.

I agree with that statement, 100%.A sway bar doesn't make your car ride rough. Tires, springs, shocks or a combination thereof.

The sway bar (or referred to stabilizer bar), front or rear is along for the ride and is only activated on turns.

They are useless on a drag racer, or someone who only drives in a straight line, or low speed turns only.

When a car is in a turn, let’s say a Left-hand turn going say 30 MPH (50 KPH). A car without a sway bar, the first motion of steering wheel will typically move the Left fender up and right fender down – instead of moving the wheels (at first). The harder the turn, the more the body tilts.

My ’67 Plymouth Satellite (340ci automatic) was built without a sway bar. When trying a series of 15-20 MPH hairpin turns, the door handles felt like they wanted to drag the pavement (because of car swaying so much). I installed a 1¼” Mopar Performance (or maybe Direct Connection) sway bar kit (made by Addco, at the time) 30 years ago, and if was so much more fun to drive those 15-20 MPH hairpin turns.

Also, after install, when you turn the steering wheel, the body feels mostly level, but wheels turn immediately. It is as if the steering gear was putting as much effort on tilting the car as it was turning, but afterwards, all effort went to quicker steering (no lost motion).

Back to SixBanger, his concerns do not point to a sway bar problem.

- Nose diving points to either front shocks and/or torsion bars. I doubt your torsion bars has gone bad – so I would look towards replacing shocks first. If it still does it, the heaver torsion bars (from Firm Feel) would be next (which are not cheap).

- The tire squeal is either alignment is off and/or bent suspension parts.

- The belt squeal leaks your P/S drive belt is still “too loose”. Just tighten it a tad bit more or replace the belt (sounds more like a wore out belt, to me).

BudW

Oldiron440

Well-Known Member

Drag cars use rear sway bars.

89.Fifth

Well-Known Member

Listen I respect your opinions, and I know you mean well, but I know what I see and feel. Having driven the same routes back to back, before and after the install, I can tell you that it affects ride quality. I can even see it in the drastically increased vibrations of the rear view mirror. In fact I'm willing to bet that if I had proper measuring equipment I could measurably quantify the difference.

Don't get me wrong, it was a nice improvement to the handling, but there is a night and day difference with and without.

Don't get me wrong, it was a nice improvement to the handling, but there is a night and day difference with and without.

SixBanger

Well-Known Member

Thank you guys! I appreciate it a lot for the information. I am going to start with the suspension and steering before I throw myself on the other components.

In addition, I am going to replace the belts of the power steering. The old were still in the trunk. But given that the previous owner has already been driving with the squeaky for a while, this can turn out.

In addition, I am going to replace the belts of the power steering. The old were still in the trunk. But given that the previous owner has already been driving with the squeaky for a while, this can turn out.

SixBanger

Well-Known Member

But I am still looking for a set of front shock with straps for a some easier installation. Does maybe someone knowing with those straps?

Otherwise I intend to make a tool to suppressed them! Something of two pairs of threaded rods with a mounting block on both side s of the shock.

Otherwise I intend to make a tool to suppressed them! Something of two pairs of threaded rods with a mounting block on both side s of the shock.

Aspen500

Well-Known Member

The problem with any kind of strap is, the shock goes basically into a hole and then the strap would be trapped. Usually they're either plastic or heavy wire straps.

What I did, with some success, was to compress the shock and then use masons line (because it's really strong) to tie it in the compressed position. Part of the string is still up in there but it worked semi OK.

What I did, with some success, was to compress the shock and then use masons line (because it's really strong) to tie it in the compressed position. Part of the string is still up in there but it worked semi OK.

lowbudget

Well-Known Member

I used baling wire on a pair of rear overloads to compress them, then clipped the wire when installed. I bulled the last pair of KYB fronts in a couple years ago, but I am not getting any younger.

SixBanger

Well-Known Member

I think it will work. Thanks!

I install shocks that are fully extended (because of no strap). 1) Get the top of the shock in its mounting hole (with the bushings and all installed) with nut on by a few threads. 2) Install a retainer and bushing on the bottom stud. 3) Use a long pickle fork (ball joint separator such as Snap-On A200, 18 inches long) with the fork of the tool against the lower bushing (straddling the stud) and using the tie rod as a fulcrum point to lever the shock compressed and move the stud over to the hole in the lower suspension arm and let it drop in the hole. 4) Finish assembly of the bushings and tighten nuts as required. That's the basics of how I do it. Works for me.

SixBanger

Well-Known Member

That is also a good idea. Thank you for your extensive explanation. Parts arrive this week.

SixBanger

Well-Known Member

Where to buy only the parts for connecting the sway bar to the k-frame (blue lines)?

The straps were useless when the front kyb's were installed. It was required to jack up one side at a time for the lower bushing/washer/nut to be installed. Or to start the nut on the lower threads at all. A royal pain as the outer edge of the control arm appeared to be the only location to jack from. And there is the chance of crushing the lower ball joint grease fitting if not super careful. And the possible lifting off the jack stands in the process. There may be an easier process but reading from the charts and books was no help at all.

SixBanger

Well-Known Member

I may have some. I can check tomorrow.

If you have them I would like to take them over from you. With the ordered set of bushings a number of connections were missing for the K-frame. When dismantling I noticed that the connection on the right was not good anymore. There is a nice margin. This also applied to the replaced bushings.