brotherGood

Well-Known Member

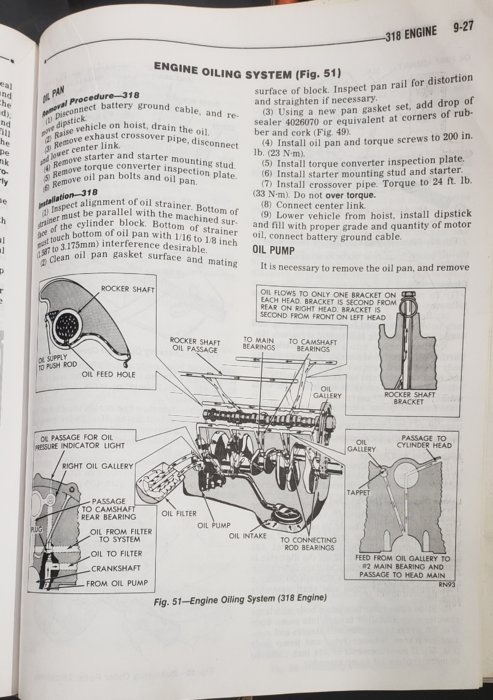

Looking for oil galley plug information, and this is the best I've found so far. For reference this is for an LA 318 with Magnum heads. Rebuilt approximately 6 years ago, maybe has 2500 miles on it.

Issue 1. Under heavy acceleration, I notice smoke coming from the passenger side. I cannot accurately tell of its coming from the exhaust or externally somewhere on the engine. When I turn the car off however, I typically can see oil on the backside of the passenger head near the bellhousing.

Issue 2. Under same conditions as above (only heavy acceleration) the passenger head makes a bunch of clattering, as if it's just simply not getting enough oil.

I do not remember seeing any drops in oil pressure, I hope to get out there this weekend and hook the gauge back up and get a solid read once more. I will notice an oil spot under the car, both while under normal conditions, and once the car is shut off. It does not leak once things have settled though, and the leak is making it's way out through a gap between the inspection cover and the bellhousing.

When the engine was first installed, dad noticed an oil leak and realized it was a galley plug and got it tight. He was only aware of the 1 leak however at the time.

Sorry for the long winded post, just wanted to give the full scoop for those with suggestions .

Thanks

Issue 1. Under heavy acceleration, I notice smoke coming from the passenger side. I cannot accurately tell of its coming from the exhaust or externally somewhere on the engine. When I turn the car off however, I typically can see oil on the backside of the passenger head near the bellhousing.

Issue 2. Under same conditions as above (only heavy acceleration) the passenger head makes a bunch of clattering, as if it's just simply not getting enough oil.

I do not remember seeing any drops in oil pressure, I hope to get out there this weekend and hook the gauge back up and get a solid read once more. I will notice an oil spot under the car, both while under normal conditions, and once the car is shut off. It does not leak once things have settled though, and the leak is making it's way out through a gap between the inspection cover and the bellhousing.

When the engine was first installed, dad noticed an oil leak and realized it was a galley plug and got it tight. He was only aware of the 1 leak however at the time.

Sorry for the long winded post, just wanted to give the full scoop for those with suggestions .

Thanks