SixBanger

Well-Known Member

Hello,

Currently I have been busy with the replacement of the valve seals in the slant.

This was easy to do with the help of a valve spring compressor and a piece of nylon wire in the cylinder.

Before I could replace the valve seals, the rocker arm assembly had to be removed.

This went fine. However, I noticed already that the last and longest mounting bolt of this assembly took some iron jacks during disassembly.

Unfortunately, when the rockers were assembled, the damage had already been done. The screw thread was already damaged in the cylinder head.

I saw that this bolt did not look original. Apparently, a replacement bolt has been fabricated and assembled. This bolt is an M10x1.5. I also see that a slot has been made with a grinding tool. Bolt shown in first picture.

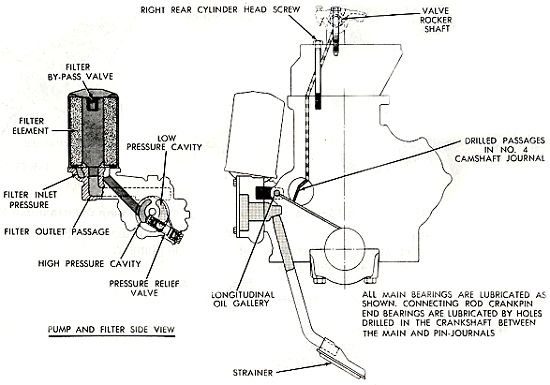

My question, is this done as an oil passage for the supply to the rockers and push rods? I have been able to find an image on the internet about how the lubrication runs in the block.

Is it possible to place a helicoil in this specific threaded hole?

Currently I have been busy with the replacement of the valve seals in the slant.

This was easy to do with the help of a valve spring compressor and a piece of nylon wire in the cylinder.

Before I could replace the valve seals, the rocker arm assembly had to be removed.

This went fine. However, I noticed already that the last and longest mounting bolt of this assembly took some iron jacks during disassembly.

Unfortunately, when the rockers were assembled, the damage had already been done. The screw thread was already damaged in the cylinder head.

I saw that this bolt did not look original. Apparently, a replacement bolt has been fabricated and assembled. This bolt is an M10x1.5. I also see that a slot has been made with a grinding tool. Bolt shown in first picture.

My question, is this done as an oil passage for the supply to the rockers and push rods? I have been able to find an image on the internet about how the lubrication runs in the block.

Is it possible to place a helicoil in this specific threaded hole?

Last edited: