SixBanger

Well-Known Member

Hi,

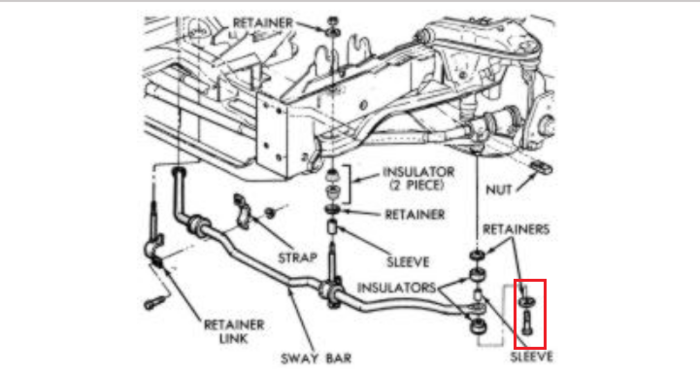

After driving for a while with the new polyurethane sway-bar bushings the steering performance is better than before.

But there is an problem with that after a speedbump one of the sleeve connection bolt just has broken off.

The bolts are 307A, grade 1, quality. So it is not the strongest bolt.

I get some grade 5 5/17 bolts. But am thinking why the bolts just broken after a while driving over speed bumps?

Can that be that the connection in the retainer link (to K-body) give to much friction? These are also new and have fit them with some silicone grease.

Or there is something wrong with the retainer link units.

Thanks!

After driving for a while with the new polyurethane sway-bar bushings the steering performance is better than before.

But there is an problem with that after a speedbump one of the sleeve connection bolt just has broken off.

The bolts are 307A, grade 1, quality. So it is not the strongest bolt.

I get some grade 5 5/17 bolts. But am thinking why the bolts just broken after a while driving over speed bumps?

Can that be that the connection in the retainer link (to K-body) give to much friction? These are also new and have fit them with some silicone grease.

Or there is something wrong with the retainer link units.

Thanks!