mattechperf

Active Member

I'm moving along with modifying the back end of my 88 Fury. I thought I'd sure some work and outline my thoughts.

The plan was to widen the wheel tubs and trim the sheet metal on the outer frame rails. All lot of room can be had without doing a complete back-half.

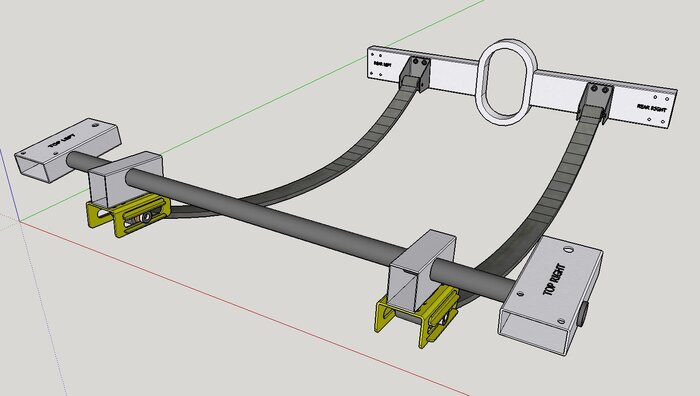

This led to the leaf springs needing to move inward. Well, that seems to be easy on the other Mopar platforms, but the M-body at least needs to go all the way to the other side of the frame rail. This will move them inward about 8 inches per side.

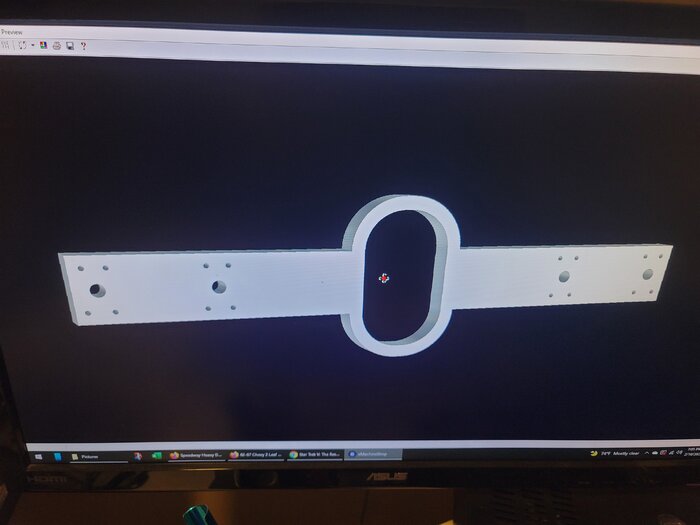

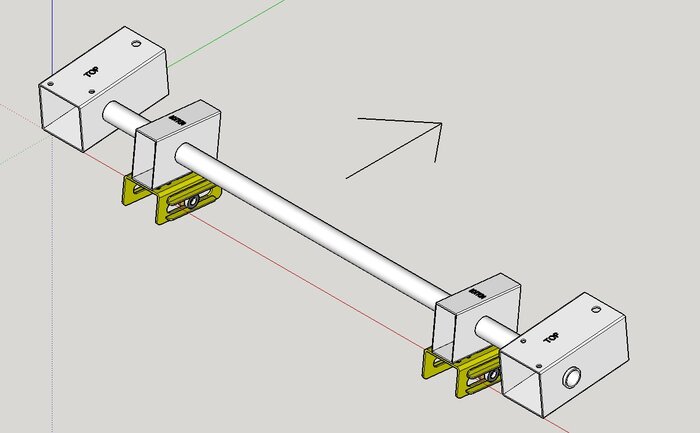

I'm building a new crossmember similar to a front mount of a ladder bar or 4-link setup, but will support the front leaf spring mounts. I'll use some 2x5" 0.120" wall square tube and a pre-made driveshaft loop from QuarterMax.

It'll bolt to the OEM spring mounts (for alignment) and will get welded into the stock frame and floor pans. This will also make a great pace to weld frame connectors to going forward under the car.

After talking with Calvert Racing, I'll go to one of their Caltrac traction bar setups and replace the rear shackles with sliders from Speedway Motors. They'll be a tad more noisy, but I plan on making plenty of noise anyway.

I'll build a few brackets to mount to the original rear spring shackle mounts on the frame and some DOM tubing will span across that where I can mount new brackets for the rear shackle/slides.

The trunk floor will definitely be in the way, but I plan on a fuel cell anyways. So, some cutting will be happening. I apologize to the purists in here.

I'm just starting on the fabrication process and need to get my nerve up before cutting the frame. Lots of measuring and re-measuring happening over the next week.

This is getting exciting!

The plan was to widen the wheel tubs and trim the sheet metal on the outer frame rails. All lot of room can be had without doing a complete back-half.

This led to the leaf springs needing to move inward. Well, that seems to be easy on the other Mopar platforms, but the M-body at least needs to go all the way to the other side of the frame rail. This will move them inward about 8 inches per side.

I'm building a new crossmember similar to a front mount of a ladder bar or 4-link setup, but will support the front leaf spring mounts. I'll use some 2x5" 0.120" wall square tube and a pre-made driveshaft loop from QuarterMax.

It'll bolt to the OEM spring mounts (for alignment) and will get welded into the stock frame and floor pans. This will also make a great pace to weld frame connectors to going forward under the car.

After talking with Calvert Racing, I'll go to one of their Caltrac traction bar setups and replace the rear shackles with sliders from Speedway Motors. They'll be a tad more noisy, but I plan on making plenty of noise anyway.

I'll build a few brackets to mount to the original rear spring shackle mounts on the frame and some DOM tubing will span across that where I can mount new brackets for the rear shackle/slides.

The trunk floor will definitely be in the way, but I plan on a fuel cell anyways. So, some cutting will be happening. I apologize to the purists in here.

I'm just starting on the fabrication process and need to get my nerve up before cutting the frame. Lots of measuring and re-measuring happening over the next week.

This is getting exciting!