About the "resize bushing".

Went to my local hardware store (Ace) and found two possibilities:

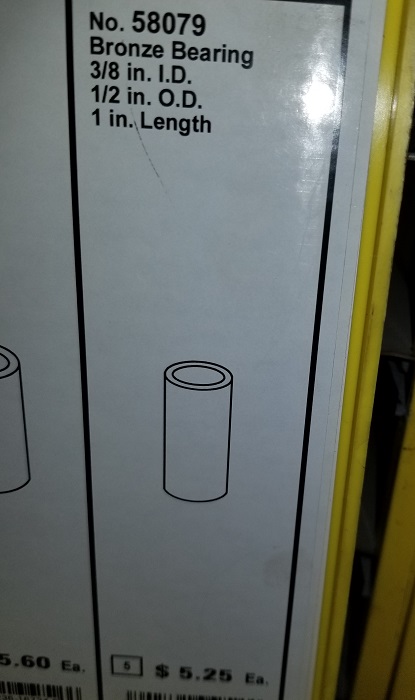

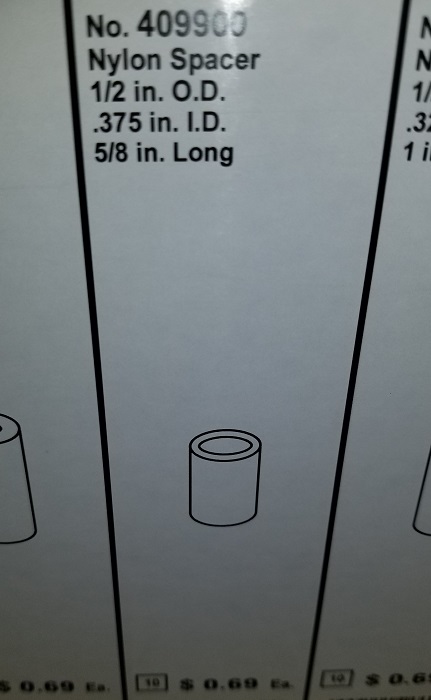

Bronze and Nylon

P/N 58079. $5.25 (plus tax, US)

P/N 409900. $0.69 (plus tax, US)

A snug fit

Also sung

Both fit fine.

Either version would need to be cut for length, which would be 1/4” long (on “K” booster). Also need to find a spacer 1/16” thick to go on side of push rod.

Note: use plenty of grease when assembling to prevent squeaks – but not too much where it might drip onto carpet (or whatever floor covering).

Personally, I recommend bronze – but I'm not sure that nylon wouldn't work just as well. I'd guess this could be topic of another discussion – but if you don't mind, lets save that discussion for another day (please) or another thread.

I'll be using the bronze version.

BudW

Went to my local hardware store (Ace) and found two possibilities:

Bronze and Nylon

P/N 58079. $5.25 (plus tax, US)

P/N 409900. $0.69 (plus tax, US)

A snug fit

Also sung

Both fit fine.

Either version would need to be cut for length, which would be 1/4” long (on “K” booster). Also need to find a spacer 1/16” thick to go on side of push rod.

Note: use plenty of grease when assembling to prevent squeaks – but not too much where it might drip onto carpet (or whatever floor covering).

Personally, I recommend bronze – but I'm not sure that nylon wouldn't work just as well. I'd guess this could be topic of another discussion – but if you don't mind, lets save that discussion for another day (please) or another thread.

I'll be using the bronze version.

BudW