Has anyone ever looked into 3D printing or happen to do 3D printing?

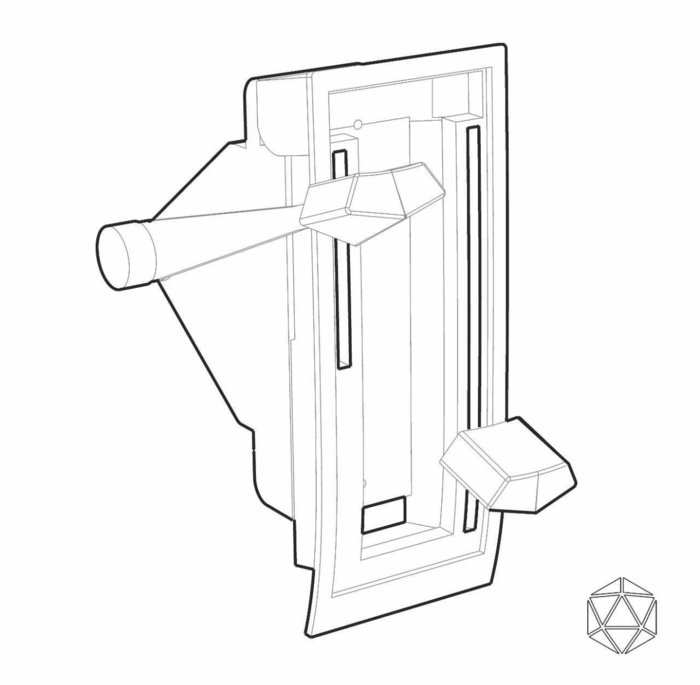

I stumbled upon a post from, Argentina where a company, 3d.Form, had 3D printed a new bezel and control knobs for an old, Mercury Montclair’s climate control system. The end product looks pretty spot on in the few pictures they posted. Idk what the cost to do stuff like this but, it seems a viable option to get one off parts made; so long as a physically sample is supplied or size/dimensions/measurements are already know. The materials used don’t seem too expensive from what I’ve seen online but, I’d imagine size and complexity of designs/shapes ect...all factor into price as well.

I stumbled upon a post from, Argentina where a company, 3d.Form, had 3D printed a new bezel and control knobs for an old, Mercury Montclair’s climate control system. The end product looks pretty spot on in the few pictures they posted. Idk what the cost to do stuff like this but, it seems a viable option to get one off parts made; so long as a physically sample is supplied or size/dimensions/measurements are already know. The materials used don’t seem too expensive from what I’ve seen online but, I’d imagine size and complexity of designs/shapes ect...all factor into price as well.