You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

removing/installing drip rail moldings

- Thread starter marty mopar

- Start date

Justwondering

Well-Known Member

wow ... seems so easy.

Mine on the fifth avenue has a screw at the leading edge (that I remember) and the entire channel was full of butyl. So it was not a simple lift and seperate.

It was more slimey and gooey and required many towels and glove changes.

Mine on the fifth avenue has a screw at the leading edge (that I remember) and the entire channel was full of butyl. So it was not a simple lift and seperate.

It was more slimey and gooey and required many towels and glove changes.

Jack Meoff

Mopar Maniac

Justwondering

Well-Known Member

My apologies, Marty.

Thank you for the video posting.

Thank you for the video posting.

Jack Meoff

Mopar Maniac

We have some newer members so I thought I'd mention that Marty is also the king of hard to damn near impossible to find NOS parts.

www.arizonaparts.com

www.arizonaparts.com

Yellowdart69

Well-Known Member

Interesting, but I couldn't figure out the tool he was using, and wouldn't putting it on, damage the paint? which leads to rust.

Justwondering

Well-Known Member

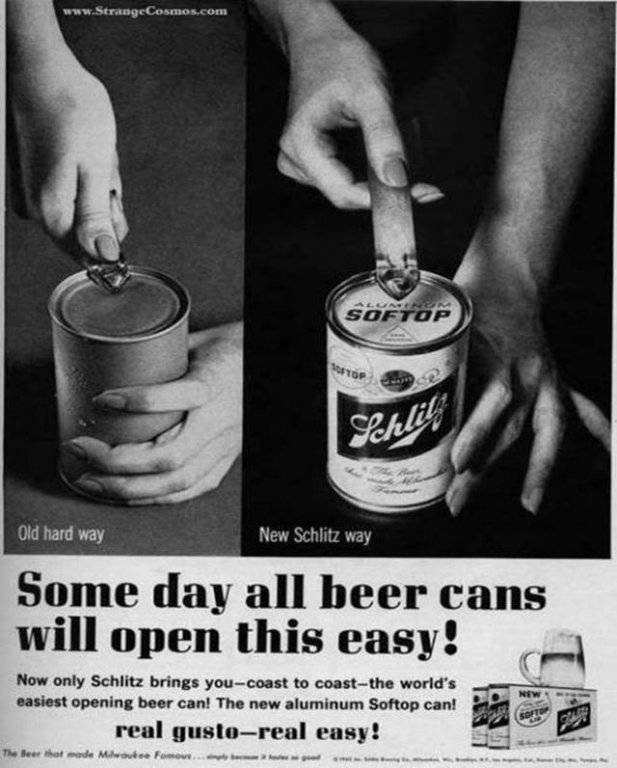

He was using a 'church' key, old fashioned bottle opener. He wrapped it with tape to keep it from scratching the molding.

Taped the end so it wouldn't scratch the molding.

This one has a sharp end, but there are ones that have a rounded front so wouldn't dig in as much.

Taped the end so it wouldn't scratch the molding.

This one has a sharp end, but there are ones that have a rounded front so wouldn't dig in as much.

Jack Meoff

Mopar Maniac

One interesting thing that was brought to my attention is that at least on M bodies that drip rail is held on by a screw at the front and I believe the rest is just tension. They don't physically snap on. I could be wrong.

Justwondering

Well-Known Member

Very true Captn,

Last year when I removed the bonnet to replace the vinyl, the drip molding was pulling away on the passenger side.

There is a screw at the front (a very rusty screw) and there was butyl the full length of the drip molding. One fastener and goo held it on. Mine didn't snap coming off or going on. Was not held on by tension.

Last year when I removed the bonnet to replace the vinyl, the drip molding was pulling away on the passenger side.

There is a screw at the front (a very rusty screw) and there was butyl the full length of the drip molding. One fastener and goo held it on. Mine didn't snap coming off or going on. Was not held on by tension.

Jack Meoff

Mopar Maniac

Very true Captn,

Last year when I removed the bonnet to replace the vinyl, the drip molding was pulling away on the passenger side.

There is a screw at the front (a very rusty screw) and there was butyl the full length of the drip molding. One fastener and goo held it on. Mine didn't snap coming off or going on. Was not held on by tension.

Thank you!

So basically the butyl is holding it in place?

Justwondering

Well-Known Member

Exactly.

On the driver side of the car, I pulled the molding after removing the screw and it was butyl all the way.

On the passenger side of the car, I pulled the molding after removing the screw and it was a layer of butyl that was partially dried with another layer of silicone over that. First owner or someone did a diy solution rather than remove and replace the dried butyl.

On the driver side of the car, I pulled the molding after removing the screw and it was butyl all the way.

On the passenger side of the car, I pulled the molding after removing the screw and it was a layer of butyl that was partially dried with another layer of silicone over that. First owner or someone did a diy solution rather than remove and replace the dried butyl.

Jack Meoff

Mopar Maniac

Exactly.

On the driver side of the car, I pulled the molding after removing the screw and it was butyl all the way.

On the passenger side of the car, I pulled the molding after removing the screw and it was a layer of butyl that was partially dried with another layer of silicone over that. First owner or someone did a diy solution rather than remove and replace the dried butyl.

Excellent info to know. Thank you!

Justwondering

Well-Known Member

Way cool.

Texas -- hmmm

Fritos (Frito Pie) and Dr. Pepper?

Margaritas?

Not just known for 3d printing, Integrated Circuits and Handheld calculators....

Although if it came right down to it, I don't think anything compares to the patents generated from Ohio in the 19th/20th centuries.

Texas -- hmmm

Fritos (Frito Pie) and Dr. Pepper?

Margaritas?

Not just known for 3d printing, Integrated Circuits and Handheld calculators....

Although if it came right down to it, I don't think anything compares to the patents generated from Ohio in the 19th/20th centuries.

Dayton, OH

- Airplane

- Self Starter for your car

- Many refrigeration advancements

- Many folks will tell you, in the day Dayton was a GM town. We had Frigedaire, Delco plants of many types, and the small truck assembly plant that built the S-10's, but the truth is that before all of that, Chrysler was here in town doing refrigeration at Chrysler Air Temp. It is now owned by the Germans, and is called Mahle-Behr Thermal.

- Pop top can

- Cash register

- The WWII decoder machine that broke the enigma codes

- The Mood Ring, a fine 70's staple

- Airplane

- Self Starter for your car

- Many refrigeration advancements

- Many folks will tell you, in the day Dayton was a GM town. We had Frigedaire, Delco plants of many types, and the small truck assembly plant that built the S-10's, but the truth is that before all of that, Chrysler was here in town doing refrigeration at Chrysler Air Temp. It is now owned by the Germans, and is called Mahle-Behr Thermal.

- Pop top can

- Cash register

- The WWII decoder machine that broke the enigma codes

- The Mood Ring, a fine 70's staple

Justwondering

Well-Known Member

Mood Ring .... goes with your bell bottoms.

Jack Meoff

Mopar Maniac

I actually had a mood ring when I was a kid.

Ok you cool Cats, and Kittens here is the true story on the ring.

I told you that NCR was here for years, cranking out those cash registers. Well in the 70's they were experimenting with the first electronic, computerized registers. You actually saw the final version of these registers at a Sears store in your neighborhood. They were the big plastic White, and Green registers that had the light up keypads that guided clerks through ringing up a sale by which keys would illuminate at a specific step in the sales process.

That register had a number of unique computer chip silicone items inside that were proprietary NCR technology. One of the engineers who was on the chip design team suddenly had a heart attack one day, from the dead line stress at work. His Doctor told him, when released from the hospital that he had to learn to relax, and understand when his body was under stress. He knew that when he was under stress his body temperature would sky-rocket. One day at work he noticed a new experimental silicone chip material that was changing color as it was heating up during testing. He wondered if he could adapt it into a ring that he could wear to monitor his body temperature. ....And as they say the rest is history.

I told you that NCR was here for years, cranking out those cash registers. Well in the 70's they were experimenting with the first electronic, computerized registers. You actually saw the final version of these registers at a Sears store in your neighborhood. They were the big plastic White, and Green registers that had the light up keypads that guided clerks through ringing up a sale by which keys would illuminate at a specific step in the sales process.

That register had a number of unique computer chip silicone items inside that were proprietary NCR technology. One of the engineers who was on the chip design team suddenly had a heart attack one day, from the dead line stress at work. His Doctor told him, when released from the hospital that he had to learn to relax, and understand when his body was under stress. He knew that when he was under stress his body temperature would sky-rocket. One day at work he noticed a new experimental silicone chip material that was changing color as it was heating up during testing. He wondered if he could adapt it into a ring that he could wear to monitor his body temperature. ....And as they say the rest is history.

Jack Meoff

Mopar Maniac

Ok you cool Cats, and Kittens here is the true story on the ring.

I told you that NCR was here for years, cranking out those cash registers. Well in the 70's they were experimenting with the first electronic, computerized registers. You actually saw the final version of these registers at a Sears store in your neighborhood. They were the big plastic White, and Green registers that had the light up keypads that guided clerks through ringing up a sale by which keys would illuminate at a specific step in the sales process.

That register had a number of unique computer chip silicone items inside that were proprietary NCR technology. One of the engineers who was on the chip design team suddenly had a heart attack one day, from the dead line stress at work. His Doctor told him, when released from the hospital that he had to learn to relax, and understand when his body was under stress. He knew that when he was under stress his body temperature would sky-rocket. One day at work he noticed a new experimental silicone chip material that was changing color as it was heating up during testing. He wondered if he could adapt it into a ring that he could wear to monitor his body temperature. ....And as they say the rest is history.

That's a very cool story.

Justwondering

Well-Known Member

And he and his pet rock lived happily ever after.