The toe is out of Alignment, Gonna get some new tires and have the Alignment Re Aligned correctly. Also will replace all bushings and go from there. Also a lot of information here for those who care to learn. Thank You

Front-End, Thrust Angle and Four-Wheel Alignment

The different types of alignments offered today are front-end, thrust angle, and four-wheel. During a front-end alignment, only the front axle's angles are measured and adjusted. Front-end alignments are fine for some vehicles featuring a solid rear axle, but confirming that the front tires are positioned directly in front of the rear tires is also important.

On a solid rear axle vehicle, this requires a thrust angle alignment that allows the technician to confirm that all four wheels are "square" with each other. Thrust angle alignments also identify vehicles that would "dog track" going down the road with the rear end offset from the front. If the thrust angle isn't zero on many solid rear axle vehicles, a trip to a frame straightening shop is required to return the rear axle to its original location.

On all vehicles with four-wheel independent suspensions, or front-wheel drive vehicles with adjustable rear suspensions, the appropriate alignment is a four-wheel alignment. This procedure "squares" the vehicle like a thrust angle alignment, and also includes measuring and adjusting the rear axle angles as well as the front.

Not all vehicles are easily adjustable or fully adjustable. Some vehicles require aftermarket kits to allow sufficient adjustment to compensate for accident damage or the change in alignment due to the installation of lowering springs.

When aligning a vehicle, it's appropriate for the vehicle to be carrying its "typical" load. This is important for drivers who continuously carry loads in their vehicles, such as sales representatives with samples or literature in the trunk. Additionally, when a vehicle is used for autocross or track events, some racers will sit in their car, or have the alignment shop "ballast" their vehicle to include the influence of the driver's weight on the suspension angles.

The primary static suspension angles that need to be measured and adjusted are caster, camber, toe and thrust angle. Here's a definition of each angle and its influence on a vehicle and its tires.

Camber

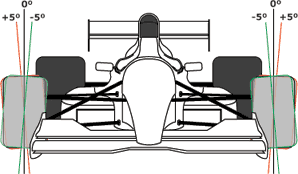

The camber angle identifies how far the tire slants away from vertical when viewed directly from the front or back of the vehicle. Camber is expressed in degrees, and is said to be negative when the top of the tire tilts inward toward the center of the vehicle and positive when the top leans away from the center of the vehicle.

Since street suspensions cannot completely compensate for the outer tire tipping towards the outside when the vehicle leans in a corner, there isn't a magical camber setting that will allow the tires to remain vertical when traveling straight down the road (for more even wear), and remain perpendicular to the road during hard cornering (for more generous grip).

Different driving styles can also influence the desired camber angle as well. An enthusiastic driver who corners faster than a reserved driver will receive more cornering grip and longer tire life from a tire aligned with more negative camber. However with the aggressive negative camber, a reserved driver's lower cornering speeds would cause the inside edges of the tires to wear faster than the outside edges.

What's the downside to negative camber? Negative camber leans both tires on the axle towards the center of the vehicle. Each tire develops an equal and offsetting "camber thrust" force (the same principle that causes a motorcycle to turn when it leans) even when the vehicle is driven straight ahead. If the vehicle encounters a bump that only causes one tire to lose some of its grip, the other tire's negative camber will push the vehicle in the direction of the tire that lost grip. The vehicle may feel more "nervous" and become more susceptible to tramlining. Excessive camber will also reduce the available straight-line grip required for rapid acceleration and hard stops.

Appropriate camber settings that take into account the vehicle and driver's aggressiveness will help balance treadwear with cornering performance. For street-driven vehicles, this means that tire wear and handling requirements must be balanced according to the driver's needs. The goal is to use enough negative camber to provide good cornering performance while not requiring the tire to put too much of its load on the inner edge while traveling in a straight line. Less negative camber (until the tire is perpendicular to the road at zero camber) typically will reduce the cornering ability, but results in more even wear.

Even though they have some of the most refined suspensions in the world, the next time you see a head-on photo of a Formula 1 car set up for a road course, notice how much negative camber is dialed into the front wheels. While this is certainly an example of wear not being as important as grip, negative camber even helps these sophisticated racing cars corner better.

Caster

The caster angle identifies the forward or backward slope of a line drawn through the upper and lower steering pivot points when viewed directly from the side of the vehicle. Caster is expressed in degrees and is measured by comparing a line running through the steering system's upper and lower pivot points (typically the upper and lower ball joints of an A-arm or wishbone suspension design, or the lower ball joint and the strut tower mount of a McPherson strut design) to a line drawn perpendicular to the ground. Caster is said to be positive if the line slopes towards the rear of the vehicle at the top, and negative if the line slopes towards the front.

A very visual example of positive caster is a motorcycle's front steering forks. The forks point forward at the bottom and slope backward at the top. This rearward slope causes the front tire to remain stable when riding straight ahead and tilt towards the inside of the corner when turned.

Caster angle settings allow the vehicle manufacturer to balance steering effort, high speed stability and front end cornering effectiveness.

Increasing the amount of positive caster will increase steering effort and straight line tracking, as well as improve high speed stability and cornering effectiveness. Positive caster also increases tire lean when cornering (almost like having more negative camber) as the steering angle is increased.

What's the downside to positive caster? If the vehicle doesn't have power steering, a noticeable increase in steering effort will be felt as positive caster is increased. Other than that, the effects of positive caster are pretty much "positive," especially increasing the lean of the tire when the vehicle is cornering while returning it to a more upright position when driving straight ahead.

Cross-Camber and Cross-Caster

Most street car alignments call for the front camber and caster settings to be adjusted to slightly different specifications on the right side of the vehicle compared to the left side. These slight side-to-side differences are called cross-camber and cross-caster.

For vehicles set up to drive on the "right" side of the road, the right side is aligned with a little more negative camber (about 1/4-degree) and a little more positive caster (again, about 1/4-degree) to help the vehicle resist the influence of crowned roads that would cause it to drift "downhill" to the right gutter. Since most roads are crowned, cross-camber and cross-caster are helpful the majority of the time, however they will cause a vehicle to drift to the left on a perfectly flat road or a road that leans to the left.

Using cross-camber and cross-caster is not necessary for track-only cars.

Toe

The toe angle identifies the exact direction the tires are pointed compared to the centerline of the vehicle when viewed from directly above. Toe is expressed in either degrees or fractions-of-an-inch, and an axle is said to have positive toe-in when imaginary lines running through the centerlines of the tires intersect in front of the vehicle and have negative toe-out when they diverge. The toe setting is typically used to help compensate for the suspension bushings compliance to enhance tire wear. Toe can also be used to adjust vehicle handling.

A rear-wheel drive vehicle "pushes" the front axle's tires as they roll along the road. Tire rolling resistance causes a little drag resulting in rearward movement of the suspension arms against their bushings. Because of this, most rear-wheel drive vehicles use some positive toe-in to compensate for the movement, enabling the tires to run parallel to each other at speed.

Conversely, a front-wheel drive vehicle "pulls" the vehicle through the front axle, resulting in forward movement of the suspension arms against their bushings. Therefore most front-wheel drive vehicles use some negative toe-out to compensate for the movement, again enabling the tires to run parallel to each other at speed.

Toe can also be used to alter a vehicle's handling traits. Increased toe-in will typically result in reduced oversteer, help steady the car and enhance high-speed stability. Increased toe-out will typically result in reduced understeer, helping free up the car, especially during initial turn-in while entering a corner.

Before adjusting toe outside the vehicle manufacturer's recommended settings to manipulate handling, be aware that toe settings will influence wet weather handling and tire wear as well.

Excessive toe settings often bring with them drivability problems, especially during heavy rain. This is because the daily pounding of tractor trailers on many highways leave ruts that fill with water. Since excessive toe means that each tire is pointed in a direction other than straight ahead, when the vehicle encounters a puddle that causes only one tire to lose some of its grip, the other tire's toe setting will push (excessive toe-in) or pull (excessive toe-out) the vehicle to the side. This may make the vehicle feel unsettled and very "nervous."

Additionally the vehicle's toe is one of the most critical alignment settings relative to tire wear. A toe setting that is just a little off its appropriate setting can make a huge difference in their wear. Consider that if the toe setting is just 1/16-inch off of its appropriate setting, each tire on that axle will scrub almost seven feet sideways every mile! Extend it out and you'll discover that rather than running parallel to each other, the front tires will scrub over 1/4-mile sideways during every 100 miles of driving! Incorrect toe will rob you of tire life.

Thrust Angle

The thrust angle is an imaginary line drawn perpendicular to the rear axle's centerline. It compares the direction that the rear axle is aimed with the centerline of the vehicle. It also confirms if the rear axle is parallel to its front axle and that the wheelbase on both sides of the vehicle is the same.

If the thrust angle is not correct on a vehicle with a solid rear axle, it often requires a trip to the frame straightening shop to correctly reposition the rear axle.

A vehicle with independent rear axles may have incorrect toe-in or toe-out on both sides of the axle, or may have toe-in on one side and toe-out on the other. The suspension on each side of the vehicle must be adjusted individually until it has reached the appropriate toe setting for its side of the vehicle.

An incorrect thrust angle is often caused by an out-of-position axle or incorrect toe settings. So in addition to the handling quirks that are the result of incorrect toe settings, thrust angles can also cause the vehicle to handle differently when turning one direction vs. the other.

Alignment Ranges

The vehicle manufacturers' alignment specifications usually identify a "preferred" angle for camber, caster and toe (with preferred thrust angle always being zero). The manufacturers also provide the acceptable "minimum" and "maximum" angles for each specification. The minimum and maximum camber and caster specifications typically result in a range that remains within plus or minus 1-degree of the preferred angle.

If for whatever reason your vehicle can't reach within the acceptable range, replacing bent parts or an aftermarket alignment kit will be required. Fortunately there is a kit for almost every popular vehicle due to the needs of body and frame shops doing crash repairs and driving enthusiasts tuning the suspensions on their cars.

Recommendations

An accurate wheel alignment is critical to balance the treadwear and performance a vehicle's tires deliver. Regular wheel alignments will usually save you as much in tire wear as they cost, and should be considered routine, preventative maintenance. Since there are "acceptable" ranges provided in the manufacturer's recommendations, the technician should be encouraged to align the vehicle to the preferred settings and not just within the range.

If you are a reserved driver, aligning your vehicle to the vehicle manufacturer's preferred settings is appropriate.

If you are an assertive driver who enjoys driving hard through the corners and expressway ramps, a performance alignment is appropriate for your car. A performance alignment consists of using the vehicle manufacturer's range of alignment specifications to maximize the tires' performance. A performance alignment calls for the manufacturer's maximum negative camber, maximum positive caster, and preferred toe settings. While remaining within the vehicle manufacturer's recommendations, these alignment settings will maximize tire performance.

If you are a competition driver who frequently runs autocross, track or road race events, you'll typically want the maximum negative camber, maximum positive caster and most aggressive toe settings available from the car and permitted by the competition rules. If the rules permit, aftermarket camber plates and caster adjustments are good investments.

Many of today's alignment machines are equipped with printouts that compare the "before" and "after" alignment angles with the manufacturers' specifications. Requesting a post alignment printout can help you confirm the thoroughness of the alignment technician and preserve a record of your vehicle's intended settings in the case of an encounter with a suspension damaging road hazard.