RobertP

New Member

Greetings All!

I'm a mechanic's son who learned pretty much the hard way how NOT to do a lot of things before I learned (or was taught) how to do them right. My Dad worked along side me on my first project a 2 door '62 Falcon Futura modified production experience that went on for 7 years, about $3,000 (in 1967 dollars) and 100,000 miles before I finally sold the car to some kids in our neighbourhood. So to summarize, I can do electrical and mechanical work bumper to bumper, body work that includes welding, straightening and fitting new metal. Think that makes me a shade tree mechanic. I don't paint and never have.

I bought this '78 Diplomat 2 - door coupe new in Edmonton Alberta in February 1978. Drove it across Canada twice in the first year. For the first 7 years of its life it lived in Edmonton and never saw salt or rust. We moved to Oshawa Ontario in July 1985 and the car started to show signs of not liking the road salt environment about three years later. It had been undercoated using some sort of dealer applied epoxy sealer. The floor pan is still in excellent shape, while the trunk floor has some rust damage where the fuel tank supports mate to the underside of the trunk floor. I was going to remove the supports and repair the trunk floor pan by hand, but could never find a 'round to it' to complete that job (humor).

In 1992 I took the vehicle off the road and began to seriously begin the restoration. Pulled the 318 and transmission and sent both out to local shops. Re-assembled the engine in my garage while the transmission was rebuilt to a factory 3 speed lockup spec. Interesting story about the engine, the oil passage for number one rod journal had never been completely drilled, so the rod only received oil from number two rod once the oil pressure came up. Always had this curious tapping noise for 214,000 Kms with each oil change that only got discovered during tear down. And as luck would prove it, the vehicle was side swiped from front bumper to rear quarter in 1980 and susequently repaired by a recognized bodyshop in Edmonton. The only thing they missed was a hole left by one of those 'T' rivets used to hold moulding clips, and as a result the left rear quarter panel slowly rusted to death from the inside before I found the root cause of the damage.

My Project Goal:

My goal was to put it back to its factory showroom look when I bought it. The vehicle is fully loaded except for power antenna; - working AM/FM - 8 track stereo, AC, cruise, tilt, power windows, locks, trunk release and power 6 way bench seat. In 1983 I removed the troublesome Lean Burn Computer (after three limp mode failures) and converted it to a standard electronic ignition. I have, but have not installed an MSD ignition system and had planned to install a Melling cam, hydraulic lifters and valve springs but decided to hold off because the laundry list of projects needed to put it down on four wheels permanently was getting a little long. Right now I want to drop the K member and replace all the body mounts, control arm bushings, ball joints and related parts to firm up the 46 year old front suspension, install new brake master cylinder / booster, calipers, rotors and rear wheel cylinders, hardware and drums. I have all the parts, just need the energy to do the work.

And speaking of parts, I have a very long list of new, and NOS parts for the project that include rocker panels, front OEM fenders (need the fenders to fix the rear quarter wheel openings - quarter panels that were no longer available in 1989 when I started parts gathering), grill, headlight doors, hood ornament, door seals, wheel opening chrome (for all four corners), lower body and rocker mouldings, door welt mouldings, gas filler door, etc - about $2,400 USD in parts (in 1989 dollars). Many of the parts are still in the factory OEM boxes. Oh yes, and a new steering wheel from Tempe, AZ. (winters in Alberta were not kind to plastic). A door panel from a Chevy Dealer in Tennessee, and many parts no longer available found across North America.

The entire interior has been removed, cleaned with seat fabric replaced with original OEM cloth found in Michigan (somewhere). Headliner and visors were re-covered and ready to go back in. Some chrome no longer available was re-chromed to show quality by Jim's Chrome and Polishing in Scarborough Ontario. This included the remote mirrors, and the crown moulding that goes over the roof line 'B' pillar where the vinyl roof meets the body. All these parts and more rest quietly in four large wardrobe boxes in our basement. Fasteners are bagged and labeled. Had the bumpers re-chromed several years ago, but not to my standards so they will likely need re-chromed again. It sits on four new Coker American Classic 1.3" whitewall tires. The original Sears M+S tires were well beyond their best before date even though they had only seen 4,000 Kms along with the drivetrain.

And then, in a moment of inspiration in 2017, I installed a BendPak full height four post lift in our garage so the project would be up out of the way and turn my two car garage into a three car. It also meant I wouldn't have to crawl around on the floor any more, and at my age, I need all the help I can get.

Current Status:

I'm seriously considering finding a reputable shop (within reasonable driving distance) that can take this running, driving chassis and do all of the mechanical and bodywork to make it paint ready. They may even paint it. That's my story, and I'm sticking to it.

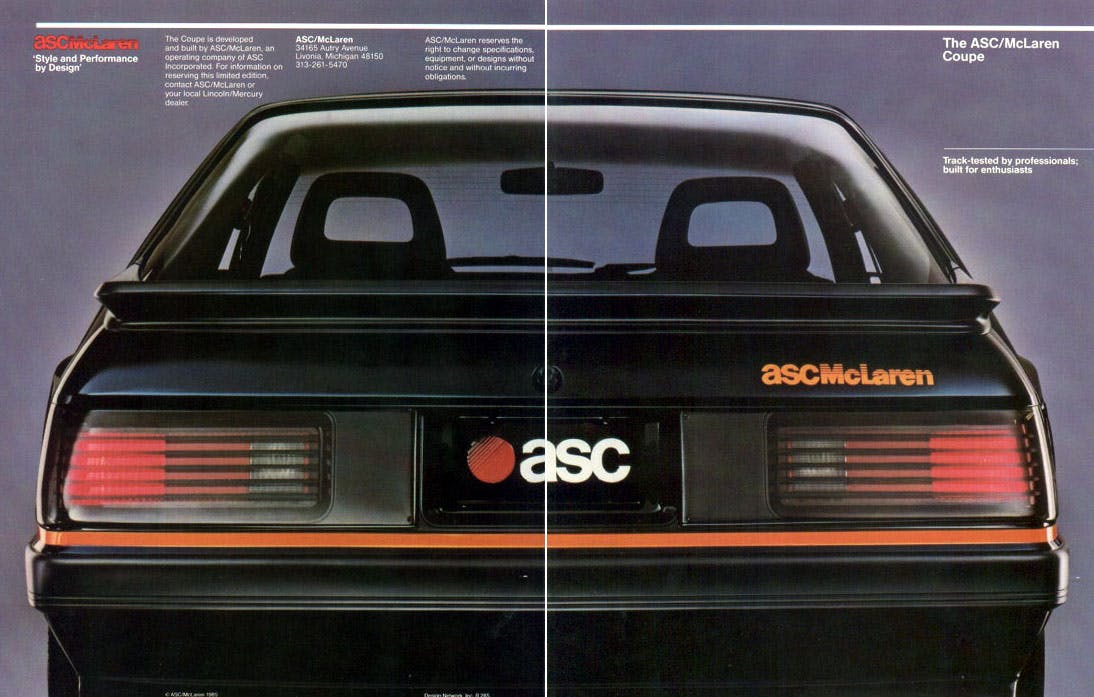

First picture is what started it all in 1968 .... The rest is history!

Robert

I'm a mechanic's son who learned pretty much the hard way how NOT to do a lot of things before I learned (or was taught) how to do them right. My Dad worked along side me on my first project a 2 door '62 Falcon Futura modified production experience that went on for 7 years, about $3,000 (in 1967 dollars) and 100,000 miles before I finally sold the car to some kids in our neighbourhood. So to summarize, I can do electrical and mechanical work bumper to bumper, body work that includes welding, straightening and fitting new metal. Think that makes me a shade tree mechanic. I don't paint and never have.

I bought this '78 Diplomat 2 - door coupe new in Edmonton Alberta in February 1978. Drove it across Canada twice in the first year. For the first 7 years of its life it lived in Edmonton and never saw salt or rust. We moved to Oshawa Ontario in July 1985 and the car started to show signs of not liking the road salt environment about three years later. It had been undercoated using some sort of dealer applied epoxy sealer. The floor pan is still in excellent shape, while the trunk floor has some rust damage where the fuel tank supports mate to the underside of the trunk floor. I was going to remove the supports and repair the trunk floor pan by hand, but could never find a 'round to it' to complete that job (humor).

In 1992 I took the vehicle off the road and began to seriously begin the restoration. Pulled the 318 and transmission and sent both out to local shops. Re-assembled the engine in my garage while the transmission was rebuilt to a factory 3 speed lockup spec. Interesting story about the engine, the oil passage for number one rod journal had never been completely drilled, so the rod only received oil from number two rod once the oil pressure came up. Always had this curious tapping noise for 214,000 Kms with each oil change that only got discovered during tear down. And as luck would prove it, the vehicle was side swiped from front bumper to rear quarter in 1980 and susequently repaired by a recognized bodyshop in Edmonton. The only thing they missed was a hole left by one of those 'T' rivets used to hold moulding clips, and as a result the left rear quarter panel slowly rusted to death from the inside before I found the root cause of the damage.

My Project Goal:

My goal was to put it back to its factory showroom look when I bought it. The vehicle is fully loaded except for power antenna; - working AM/FM - 8 track stereo, AC, cruise, tilt, power windows, locks, trunk release and power 6 way bench seat. In 1983 I removed the troublesome Lean Burn Computer (after three limp mode failures) and converted it to a standard electronic ignition. I have, but have not installed an MSD ignition system and had planned to install a Melling cam, hydraulic lifters and valve springs but decided to hold off because the laundry list of projects needed to put it down on four wheels permanently was getting a little long. Right now I want to drop the K member and replace all the body mounts, control arm bushings, ball joints and related parts to firm up the 46 year old front suspension, install new brake master cylinder / booster, calipers, rotors and rear wheel cylinders, hardware and drums. I have all the parts, just need the energy to do the work.

And speaking of parts, I have a very long list of new, and NOS parts for the project that include rocker panels, front OEM fenders (need the fenders to fix the rear quarter wheel openings - quarter panels that were no longer available in 1989 when I started parts gathering), grill, headlight doors, hood ornament, door seals, wheel opening chrome (for all four corners), lower body and rocker mouldings, door welt mouldings, gas filler door, etc - about $2,400 USD in parts (in 1989 dollars). Many of the parts are still in the factory OEM boxes. Oh yes, and a new steering wheel from Tempe, AZ. (winters in Alberta were not kind to plastic). A door panel from a Chevy Dealer in Tennessee, and many parts no longer available found across North America.

The entire interior has been removed, cleaned with seat fabric replaced with original OEM cloth found in Michigan (somewhere). Headliner and visors were re-covered and ready to go back in. Some chrome no longer available was re-chromed to show quality by Jim's Chrome and Polishing in Scarborough Ontario. This included the remote mirrors, and the crown moulding that goes over the roof line 'B' pillar where the vinyl roof meets the body. All these parts and more rest quietly in four large wardrobe boxes in our basement. Fasteners are bagged and labeled. Had the bumpers re-chromed several years ago, but not to my standards so they will likely need re-chromed again. It sits on four new Coker American Classic 1.3" whitewall tires. The original Sears M+S tires were well beyond their best before date even though they had only seen 4,000 Kms along with the drivetrain.

And then, in a moment of inspiration in 2017, I installed a BendPak full height four post lift in our garage so the project would be up out of the way and turn my two car garage into a three car. It also meant I wouldn't have to crawl around on the floor any more, and at my age, I need all the help I can get.

Current Status:

I'm seriously considering finding a reputable shop (within reasonable driving distance) that can take this running, driving chassis and do all of the mechanical and bodywork to make it paint ready. They may even paint it. That's my story, and I'm sticking to it.

First picture is what started it all in 1968 .... The rest is history!

Robert

Last edited: