Are you not able to get your FMJ into alignment (not enough provision for positive Camber)?

There are three fixes (that I know of):

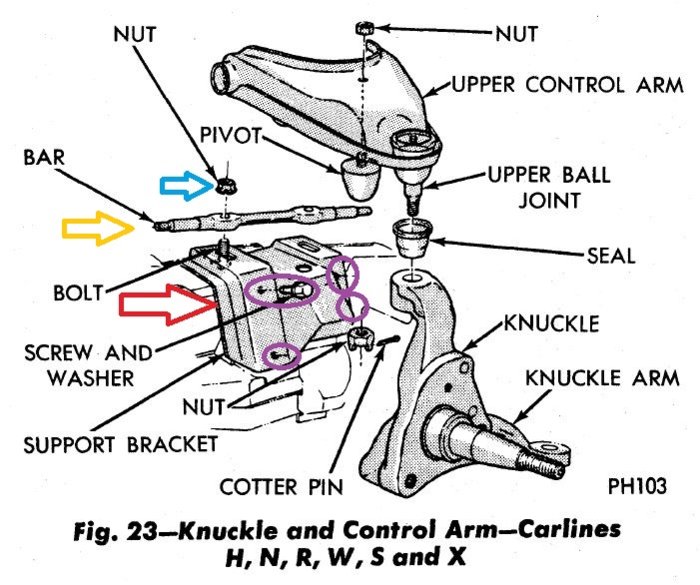

The first option is to remove the upper control arm support plate (or plates, if both sides are needed) – Red arrow. Once plates are removed, you need to grind on or lengthen the slot (towards the wheel or outside of car) - Just don’t carried away with the grinding. Deburr the slots, then reassemble the suspension.

Option two is to remove the upper control arms, dissemble the arms and replace the upper cross shaft/bar with an offset shaft (gold arrow, above). New control arm bushings are installed at same time (which most of us might need new bushings, anyway). Here is a picture of an offset shaft (made (or were made...) by a few different companies):

Part numbers are (and there might be others):

Rare Parts RP15177

Moog K7091

TRW 13261a

Note: it is “best” to tighten the upper control arm bar nuts to specs (110-ft/lb. or 489 nm) after bushing replacement, when car is at “ride height”. If this is not done, the bushing is twisted and will wear out faster.

Option three (my recommendation) is based off a Chrysler TSB (Technical Service Bulletin). I thought I had a copy of this of this TSB in my records but couldn’t find it. This data was copied from Alldata:

1983-1987 Gran Fury, Diplomat & 5th Avenue

Subject

Insufficient Positive Camber Adjustment

Index

FRONT SUSPENSION

Date

December 22, 1986

No. 02-05-86 REVISION A P-4482

This bulletin supersedes Technical Service Bulletin 02-05-86, which should be removed from your files. The rear spacer part number has been corrected to PN 4014353, and labor operation numbers and time have been assigned.

SYMPTOM/CONDITION

Insufficient positive camber adjustment.

PARTS REQUIRED

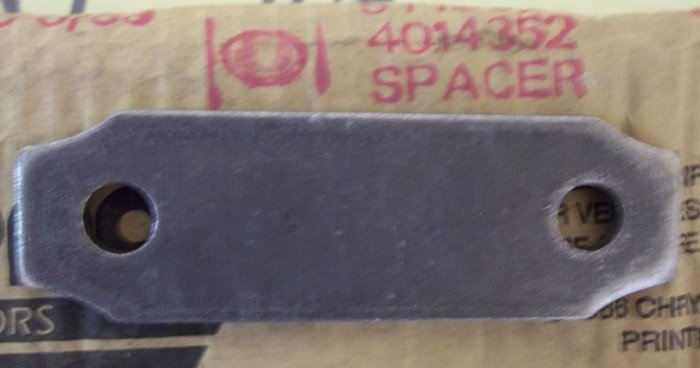

1 Spacer, Front Suspension Upper PN 4014352

Control Arm Pivot Support - Front

1 Spacer, Front Suspension Upper PN 4014353

Control Arm Pivot Support - Rear

REPAIR PROCEDURE

This repair outlines the installation of upper control arm support plate spacers.

1. Loosen the caster/camber adjusting nuts (not necessary to remove them).

2. Raise car and remove wheel.

3. Loosen shock absorber upper nut (not necessary to remove).

4. Remove the two (2) support plate bolts at the front end of the plate.

5. Loosen the two (2) rear bolts enough to slide the front spacer (longer of two) between the support plate and the frame.

6. Align the holes in the spacer with the holes in the support plate and frame.

7. Insert the two front bolts and start threads. Do not tighten.

8. Repeat Steps 5 through 7 for the rear spacer (shorter of two).

9. Torque the four (4) support plate bolts to specification (65 foot pounds).

10. Torque the shock absorber upper nut to specification (25 foot pounds).

11. Replace wheel on car.

12. Lower the car and adjust the alignment on the side where the spacers were installed according to the procedures and specifications in the service manual.

NOTE: THE UPPER CONTROL ARM SPACERS ARE TO BE USED ONLY AS A SET (1 LONG AND 1 SHORT) ON THE SIDE WHERE THEY ARE NEEDED. UNDER NO CIRCUMSTANCES ARE SPACERS TO BE STACKED TO GAIN ADDITIONAL POSITIVE CAMBER ADJUSTMENT.

POLICY: Reimbursable within the provisions of the warranty

TIME ALLOWANCE:

Labor Operation No. 02-10-55-90 . . . . . . . . . 1.8 Hrs.

Includes Shim One Side and Align Front End

02-10-55-91 . . . . . . . . . 2.5 Hrs.

Includes Shim Both Sides and Align Front End

FAILURE CODE: 50 - Improper Adjustment

Decades ago, I had a handfuls of the spacer plates mentioned in Option three. Now I don’t. I do plan on getting an example of each and placing the measurements here (once obtained). I “believe” the spacers are 3/16” (4.8 mm) thick – but I see no reason why 1/4” (6.4 mm) thick stock wouldn’t work. I do recommend replacing the four (per side) support bracket to K-frame bolts with grade 8 bolts – if using these spacers.

EDIT: the factory shims are verified to be 1/4" think (and not 3/16" as I had suspected).

4014352

4014353

Option four does not allow for more adjustment – but does help strengthen the upper control arm support plates (helps prevent it from bending). This is part of a recall for F-bodies:

1977 Plymouth Volare Suspension Recall 78V097000

Action Number: N/A

Service Bulletin Number: 78V097000

Report Date: May 01, 1978

Component: Suspension

Potential Units Affected: 1,100,000

Manufacturer: Chrysler Corporation

Summary: Possible fatigue failure can occur in the frame support plates (front suspension pivot bar support plate) that connects a portion of the front suspension to the vehicle frame on the involved vehicles.

Consequence:

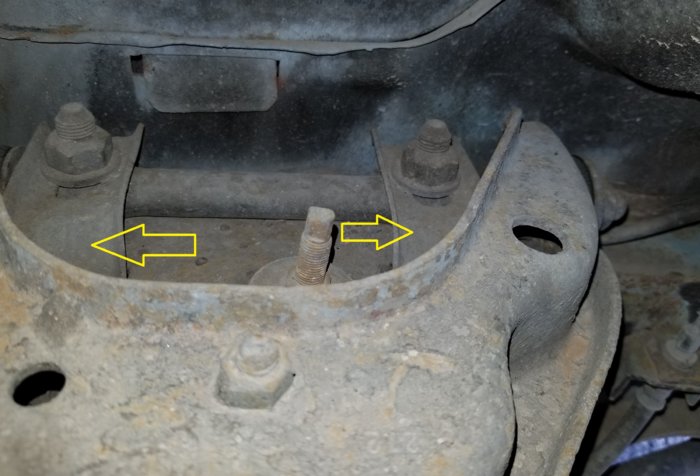

Remedy: The dealer will inspect support plates for indications of failure and, if necessary, will replace the plates. Additional support brackets will also be installed to reinforce the support plate at the pivot bar attachments.

Notes: Vehicle description: passenger vehicles. System: suspension; frame support plate. Consequences of defect: under certain driving conditions, this failure could affect vehicle directional control, particularly during heavy brake application. This will result in loss of vehicle control without prior warning and a vehicle accident.

This is a picture of the additional parts already installed (on my ’77 Volare) - yellow arrows:

If you can find these parts (used, and in decent condition), this is a great way to beef up any FMJ suspension system.

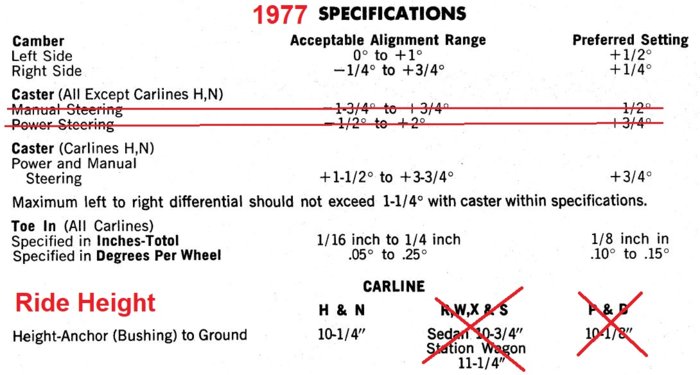

Factory alignment specifications are:

From my 1977 FSM (Factory Service Manual) for F and M-body

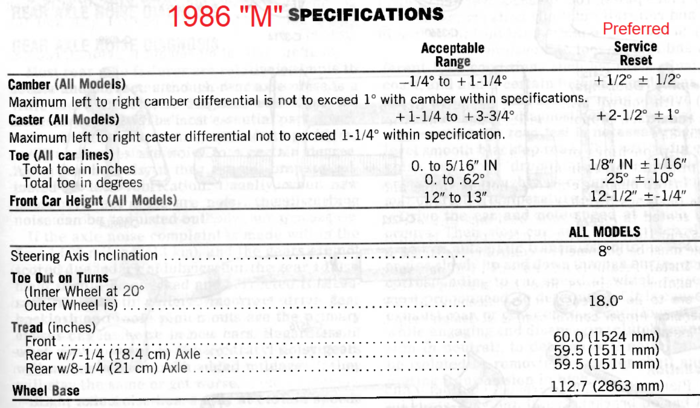

From my 1986 FSM (for M-body)

To recap, "official" ride height is from bottom of lower control arm to ground.

BudW

There are three fixes (that I know of):

The first option is to remove the upper control arm support plate (or plates, if both sides are needed) – Red arrow. Once plates are removed, you need to grind on or lengthen the slot (towards the wheel or outside of car) - Just don’t carried away with the grinding. Deburr the slots, then reassemble the suspension.

Option two is to remove the upper control arms, dissemble the arms and replace the upper cross shaft/bar with an offset shaft (gold arrow, above). New control arm bushings are installed at same time (which most of us might need new bushings, anyway). Here is a picture of an offset shaft (made (or were made...) by a few different companies):

Part numbers are (and there might be others):

Rare Parts RP15177

Moog K7091

TRW 13261a

Note: it is “best” to tighten the upper control arm bar nuts to specs (110-ft/lb. or 489 nm) after bushing replacement, when car is at “ride height”. If this is not done, the bushing is twisted and will wear out faster.

Option three (my recommendation) is based off a Chrysler TSB (Technical Service Bulletin). I thought I had a copy of this of this TSB in my records but couldn’t find it. This data was copied from Alldata:

1983-1987 Gran Fury, Diplomat & 5th Avenue

Subject

Insufficient Positive Camber Adjustment

Index

FRONT SUSPENSION

Date

December 22, 1986

No. 02-05-86 REVISION A P-4482

This bulletin supersedes Technical Service Bulletin 02-05-86, which should be removed from your files. The rear spacer part number has been corrected to PN 4014353, and labor operation numbers and time have been assigned.

SYMPTOM/CONDITION

Insufficient positive camber adjustment.

PARTS REQUIRED

1 Spacer, Front Suspension Upper PN 4014352

Control Arm Pivot Support - Front

1 Spacer, Front Suspension Upper PN 4014353

Control Arm Pivot Support - Rear

REPAIR PROCEDURE

This repair outlines the installation of upper control arm support plate spacers.

1. Loosen the caster/camber adjusting nuts (not necessary to remove them).

2. Raise car and remove wheel.

3. Loosen shock absorber upper nut (not necessary to remove).

4. Remove the two (2) support plate bolts at the front end of the plate.

5. Loosen the two (2) rear bolts enough to slide the front spacer (longer of two) between the support plate and the frame.

6. Align the holes in the spacer with the holes in the support plate and frame.

7. Insert the two front bolts and start threads. Do not tighten.

8. Repeat Steps 5 through 7 for the rear spacer (shorter of two).

9. Torque the four (4) support plate bolts to specification (65 foot pounds).

10. Torque the shock absorber upper nut to specification (25 foot pounds).

11. Replace wheel on car.

12. Lower the car and adjust the alignment on the side where the spacers were installed according to the procedures and specifications in the service manual.

NOTE: THE UPPER CONTROL ARM SPACERS ARE TO BE USED ONLY AS A SET (1 LONG AND 1 SHORT) ON THE SIDE WHERE THEY ARE NEEDED. UNDER NO CIRCUMSTANCES ARE SPACERS TO BE STACKED TO GAIN ADDITIONAL POSITIVE CAMBER ADJUSTMENT.

POLICY: Reimbursable within the provisions of the warranty

TIME ALLOWANCE:

Labor Operation No. 02-10-55-90 . . . . . . . . . 1.8 Hrs.

Includes Shim One Side and Align Front End

02-10-55-91 . . . . . . . . . 2.5 Hrs.

Includes Shim Both Sides and Align Front End

FAILURE CODE: 50 - Improper Adjustment

Decades ago, I had a handfuls of the spacer plates mentioned in Option three. Now I don’t. I do plan on getting an example of each and placing the measurements here (once obtained). I “believe” the spacers are 3/16” (4.8 mm) thick – but I see no reason why 1/4” (6.4 mm) thick stock wouldn’t work. I do recommend replacing the four (per side) support bracket to K-frame bolts with grade 8 bolts – if using these spacers.

EDIT: the factory shims are verified to be 1/4" think (and not 3/16" as I had suspected).

4014352

4014353

Option four does not allow for more adjustment – but does help strengthen the upper control arm support plates (helps prevent it from bending). This is part of a recall for F-bodies:

1977 Plymouth Volare Suspension Recall 78V097000

Action Number: N/A

Service Bulletin Number: 78V097000

Report Date: May 01, 1978

Component: Suspension

Potential Units Affected: 1,100,000

Manufacturer: Chrysler Corporation

Summary: Possible fatigue failure can occur in the frame support plates (front suspension pivot bar support plate) that connects a portion of the front suspension to the vehicle frame on the involved vehicles.

Consequence:

Remedy: The dealer will inspect support plates for indications of failure and, if necessary, will replace the plates. Additional support brackets will also be installed to reinforce the support plate at the pivot bar attachments.

Notes: Vehicle description: passenger vehicles. System: suspension; frame support plate. Consequences of defect: under certain driving conditions, this failure could affect vehicle directional control, particularly during heavy brake application. This will result in loss of vehicle control without prior warning and a vehicle accident.

This is a picture of the additional parts already installed (on my ’77 Volare) - yellow arrows:

If you can find these parts (used, and in decent condition), this is a great way to beef up any FMJ suspension system.

Factory alignment specifications are:

From my 1977 FSM (Factory Service Manual) for F and M-body

From my 1986 FSM (for M-body)

To recap, "official" ride height is from bottom of lower control arm to ground.

BudW

Last edited: