9023S. So 9023.....

I really need to know how to set the metering rods up, I can't find anything on the interweb. That maybe my off idle stumble

Off idle stumble is almost always one or, or a combination of, the following items.

1) fuel level ,

2) ignition timing

3) transfer slot synchronization/ ignition timing,

3b) throttle valve synchronization

4) Accelerator pump shot,

5)PCV or vacuum leaks

Check these first before you start messing with the metering rods.

Check/adjust them in the order listed.

If not a stock engine,post up what you got, but

for a stocker or near stock (no cam);.

1) The correct fuel level establishes the ease of fuel pullover,but

The further your transfer slots are from ideal, the less a fuel level correction will affect a change, unless it's really out to lunch. Always always start with an accurate fuel level.On the chance that you have already done this, you can skip over this for now; and do the rest first, it's just easier. If we still have a problem later, then we can come back to this at that time.

2) Set the timing back to stock.If you have a buncha vacuum controlled devices, those all have to be working and plumbed. We can talk about those later. Right now, your carb is calibrated for all those devices to be working, and if they are not, then you will be fiddle-farting around until you accidentally hit the magic combo, or forever if you don't..

3) The transfers are your basic low speed circuit. But if your timing is out of spec then the transfer slots will be too; you cannot arbitrarily crank up the timing because somebody told you to. So, here's how to set those;

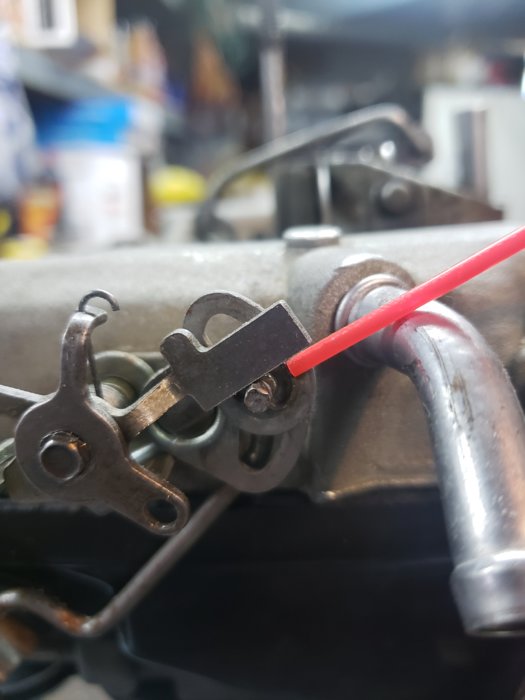

Take the carb off, make sure the throttle valves are not on the fast idle cam. Make sure they are on the curb-idle screw.Then flip it upside down and Now is the time to check

3b.

Unscrew the curb-idle speed screw until the throttle valves are BOTH touching the throttle bores and they are simultaneously both sealing the bores. If this does not happen, then it is because either; the throttle shaft bushings are worn or, one or both throttle valves are bent or, one or both is not centered on the shaft, or the secondary link is too tight. Find and fix the problem before continuing.

Ok now,go find the Transfer-slots in the primary bores.Start on the drivers side cuz, IIRC that side has only the one vertical slot. Now go to the passenger side and find the matching one.

Now with the throttles closed, but not jammed closed, using the curb-idle screw, adjust the transfer slot exposure,with the carb still upside down, until the slot is a tiny bit taller than it is wide. Just enough taller that you don't have to squint to see it. Double check that what you did,matches what I typed.

From now on, leave that speed screw alone!. you will be using timing to set the idle speed

Ok now, figure out how to make this adjustment with the carb NOT upside down, cuz I can almost guarantee that you are gonna want to turn the speed screw, and if you do, then you just screwed up a half an hour. And I will not be happy!lol. The usual method is toback off the speed screw,counting the number of turns it takes to fully close the throttles but not lift the screw off the adjusting lug. Right it Down, dogone it. Then put it back to where you found it.

One more thing; make sure the secondaries close up tight at the new curb-idle screw setting; tightly closed but not sticking.... both of them the same.

Now reset the low-speed mixture screws to 2.0 turns. These are NOT your low-speed fuel system; they are just idle trimmers. Do not try use them to idle your engine on, cuz I GUARANTEE that will cause trouble; they are just trimmers.

4) every time you change the idle speed, you will/may have to reset the Accelerator pump starting point. This circuit on a Holley has to be functioning perfectly. But on a TQ, if you get the basics set right on a mechanically sound engine, then it can be a little off base and you might never know it. Which is good cuz sometimes on TQs this circuit is a PITA to get working right. The bottom line is yes, the pump should deliver fuel at the slightest tickling of the throttle valves, and it should be a spray not a dribble or a frothy dribble. You may have to stroke it several times to prime the circuit. But wait until there's fuel in the bowls!,lol, to check this.

5) Make sure you got a good working PCV, and no vacuum leaks. How can you know about the PCV? I don't know either, for $5.00 i just get a new correct for the application one, make sure it rattles when I shake it,and shuts off when I blow into it,then stick it on there. It will be fine.

>Ok after you get all this done, you can reinstall it, prime it, fire it up, and warm the engine up.

Do not touch the curb-idle screw! If she won't stay running, put her up on the fast idle cam, until she's warm and happy.

After she's warmed up, kick her off the fast idle.

If she stalls;

Do not adjust the curb idle screw! Put a vacuum gauge on the intake manifold, pull some timing in, just tug on the D and rotate her about a half inch, right now it don't matter how much, we just want a running engine. Ok fire it up.

If she's running faster than 750, retard the timing until it gets down to there, still on the curb-idle screw.Then check the idle vacuum.

Still on a stock engine, I'm looking for 15 inches at 750rpm, or more.

If you're there, and this is an automatic car; then, have a helper step on the brake and put her into gear, then check the vacuum and the rpm. If the engine is happy, then retard the timing until you see 600/650 with a happy engine. Finally still in gear, adjust the mixture screws, both the same, up to 1 turn either way, to make the engine as happy as she can be.

Now if the vacuum falls below .......... I'll guess 12 inches while doing this; or if the engine won't idle at 650 in gear; then STOP! something is wrong. Now put it back into park. And we can talk about that in another post.

But if it took thatchit, then, put a timing light on it and let's see where she's at.