Bruce, I just found this thread (been a bit behind on things, lately.

I like your drawings and photos – for (IMO) they are helpful.

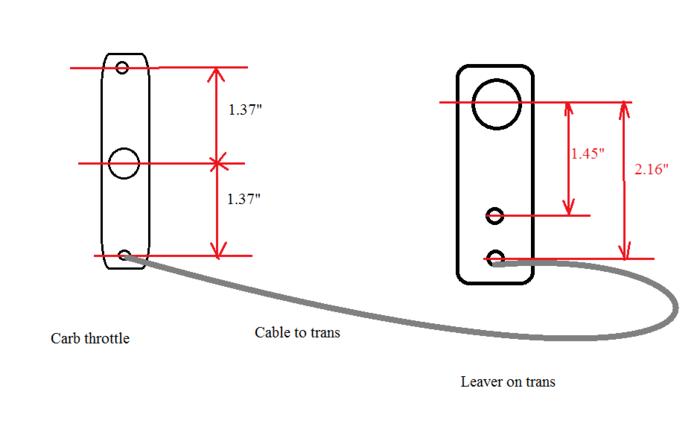

The lever on transmission and carburetor are meant to be 1to1 ratio.

That said, sometimes on the 3-piece setups, they don’t have room to make the bell cranks 1:1 – so the different holes are to compensate for that,

Next. The location of cable attachment (both ends) and location of cable to lever points (both ends) also make a difference.

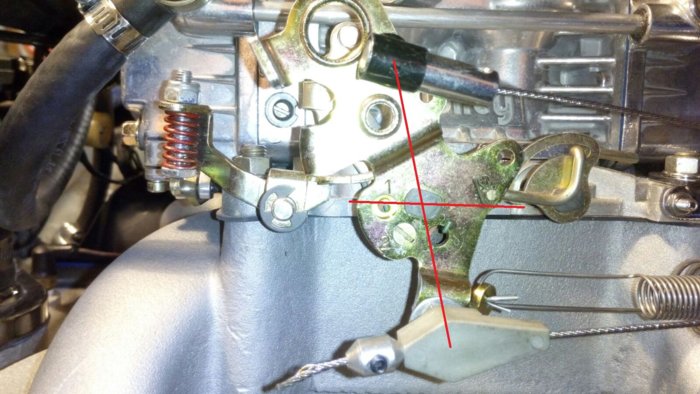

See the cable attachment (in your picture, but modified) at point A and point B. It messes with a lot of the geometry of things when they are off.

The transmission is where I see a possible issue (see red and yellow lines. I would “think” the cable attachment should be in line with the lower black line. Being it is at an angle, it appears to possibly be a geometry error (if that makes any sense.

To give an idea on what I’m saying, I added “A” and “B” with cable attachment points (red circles) to top picture.

I think in this case (without reading the web site), I would change the transmission lever cable point to the inner hole first, and retry it. I think that as well as maybe making a different transmission cable attachment point (tail housing) would make a world of difference).

You cannot adjust the line pressure without taking the pan off. To solve this, I drilled and tapped a small hole in the case, directly behind the adjustment screw, so I could insert an allen wrench there from the outside. This adjustment is very sensitive, so 1 turn is a lot. But during the initial set-up stage, 1 turn is about right. Install the access-plug-you won't be sorry.

I love that idea!

I’ve taken transmission pans down until I was literally red in the face (sic), to adjust line pressures – so I will start to do that on “modified” transmissions.

BudW