Now that I can see the picture better, this is troubling (that much metal).

Things to inspect, while transmission is out:

Take a bright flashlight and check for any cracks around the six crankshaft bolt holes and around the four torque converter bolt holes. I doubt you have any – but well worth the effort to look before reassembly.

Look for cracks around the torque converter hub at the two machined slots. It is common for the metal hub to crack there. Also, check the smoothness of the hub with your fingernail. It should not catch anything. If your fingernail catches or there is a crack present – replace the converter. If both are good, then take existing converter to a torque converter shop to get flushed out. The converter holds more fluid than rest of transmission and very difficult for most people to even get most fluid out (not counting metal shavings. A converter flush costs about ½ the cost of converter replacement in my area.

With the potential cracks in valve body. Look on other side of the valve body to see if anything can be seen from other side. I suspect nothing is present on other side. If that is correct, then continue on. If there is a crack or is a porous casting, then epoxy (on outside of valve body) might fix it. Either way, I don't think it is much to worry about.

With that much metal present – I do recommend going completely though the transmission, including the valve body.

For major overhauls, I prefer to use two tables/workbenches. One table to work on and the other table with parts laid out (in order of removal). I also recommend using either a “clean” tarp or plastic to cover your parts with when not actively working on it. Dirt is the huge enemy of automatic transmissions (as well as bugs and other things. Also, I like to have lots of "clean" cardboard on both tables. If you drop something (which happens with wet fingers), the cardboard will prevent damage and soak up some spills. After I remove the different assemblies, I will then rebuild each assembly in order of removal. If in doubt, use a sharpie marker on the cardboard. You can't make enough notes on these things, expecially on your first time. Also, lots and lots of camera pictures is also very helpful.

When reassembling, I recommend getting a small tub of petroleum jelly. Use some jelly to help hold those bushings and thrust washers in place when going together. The jelly will dissolve in the fluid. Not hurting anything (it is what factory and transmission rebuilders use).

An example. I would use whatever is cheapest.

Also get a disposable small container large enough to place your new clutch disks into. Those disks are made out of paper and need to soak in ATF for at least an hour before use. Same for the two bands if replacing with new (they don't need to soak as long). Reusing bands or disks, a quick dip in ATF should work fine.

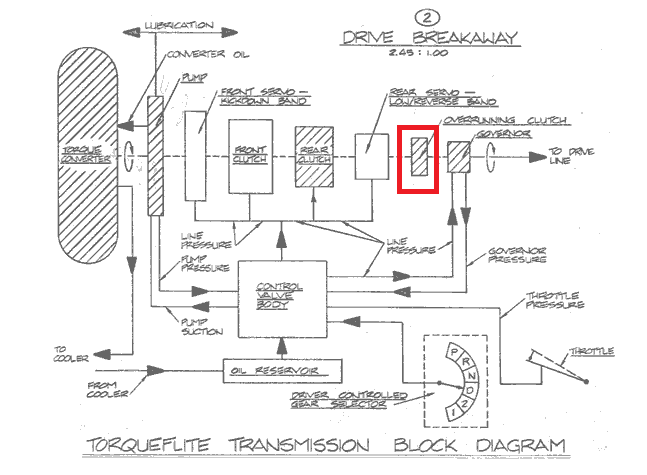

Look at the overrunning clutch. Using needle-nose pliers, you can remove the springs to look at questionable ones. If all look, OK, then reuse them.

If a problem with one spring is found, replace them all. I don't see much problems with the cam. They can be very difficult to replace if you do have a problem with one.

Install the front band just before installing the front pump and after installing the two clutch drums. It makes getting the two clutch drums in easier (less fighting with the band). After everything is ready for the front pump to be installed, tighten the front band (snug but not tight) to help hold things together for the pump.

I do recommend dissembling the front pump to clean out any metal and to check condition of converter hub bushing (and to change the seal). To assemble the front pump, get a pair of longer bolts that fit the threads used for slide hammer (3/8”-16 I think – but don't quote me on that) and cut off the heads to use as pilot studs (or long enough to use as a guide to get pump back together. All-thread can work. The assembling tool might be hard to get your hands on – for it is a rather large diameter. You have a lot of options but having a second pair of hands is very helpful. Use of thin sheet steel, plastic or even an old leather belt works. I prefer to install the two halves together the opposite direction shown (pilot studs pointing down and pump gears already in outermost housing – so the alignment tool wouldn't be needed. A couple blocks of wood is helpful.

Apply a lot of ATF to the (front pump) big square-cut O-ring and to the case before inserting pump.

The (outer) pump bolts have plated metal washers/seals (see purple circle, three pictures down). I recommend installing the pump, make sure your end play is correct and such, and once happy with all of that, remove the pump bolts and install those seals LAST. Those seals are “wet” and can be under a bit of pressure – so is a potential (and very common) leak area. Those seals will be damaged with constant tightening/loosening/tightening, which is why I install them

after any pump business is done.

Also get a pair of long bolts and cut heads off to use as pilot studs. On these pilot studs, it does help to round the ends as well as slot the ends so a screwdriver can remove them after pump is in place. I addition, it helps to get a pair of (again, I think are 3/8”-16 bolts) of 3 to 5 inch long) to use as handles (in the same holes the slide hammers use) to help hold pump while inserting it

Note: the pilot studs used here (above) will be in same holes as your pair of "handle" bolts will be in (a poor picture).

The "handle" bolt locations.

When tightening the pump bolts, take it slow and criss-cross the bolts to tighten. At same time, keep checking the input shaft. It should not get hard to turn when tightening bolts. If it does, STOP!. Take the pump off and start to check if any thrust washers fell out of place. It takes a while, but this step has saved a lot of ruined parts, grief and time.

Getting the end play set correctly is important (might be the most important item), even if you have to wait a while to get the correct thickness thrust washer(s).

It would have been nice to measure the end play

before disassembly (which may or might not of happened).

Continued