I have taken apart almost new transmissions. The thrust washers are made of a few different materials and it looks odd (or looks wore out) but most thrust washers are usually still within specifications. I don't get excited about “worn looking” washers. Now missing fingers or embedded metal or other things like that, I do get concerned about.

Something made of steel is creating the iron shavings. Check all parts for metal on metal wear. Check the planetary gears for looseness, and so forth. If you can't find an obvious source of the metal, then change the torque converter! If the converter came apart, there will be metal EVERYWHERE inside (in every passage, every bore and in every crevice). The fluid from converter goes to the transmission cooler, then as lube for all parts inside of transmission. There is nothing to filter the metal shavings out after fluid leaves the converter

Take the governor off (behind the tailhousing. You don't have to mess with the four bolts with lock tab. The removal of snap rings and taking out the pin, it should slide off. Those weights should slide inside of their bores with little effort.

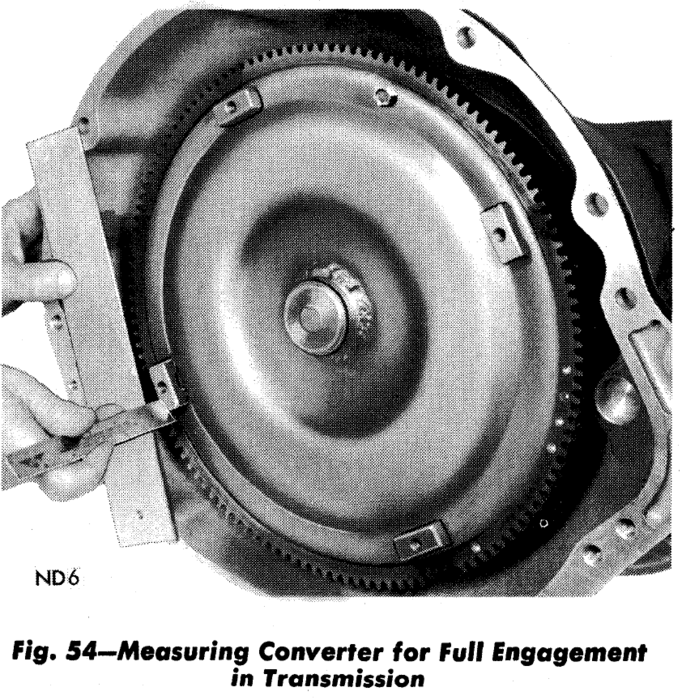

When converter is in place, it should be about 1/2" (13 mm) in above picture. You will need to rotate the converter (a lot) while pushing on it (not hard). You should feel three distinct clunks as the three items line up. Make sure the front pump seal is well lubricated with ATF before inserting the converter.

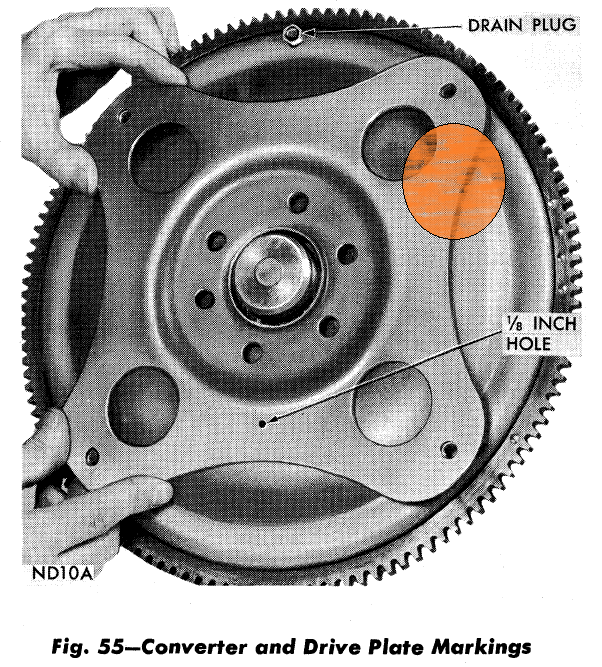

Before transmission removal, I like to take a bit of spray paint (sharpie, or whatever) and mark one of the flex plate lugs like this:

How or what color doesn't matter. The four torque converter bolts will only all go in, in one manor. If you have two (or three) that line up, but not the forth, you have to stop, remove all bolts, rotate and try again (a big pain in the ____). A person could remove the flexplate, but that is also additional labor.

Note: your converter WILL NOT have a drain plug. Your converter might have a "V" stamped in it (in place of the drain plug) - but sometimes that mark is not present, either.

Hopefully you found a detailed service manual for this transmission.

BudW

Something made of steel is creating the iron shavings. Check all parts for metal on metal wear. Check the planetary gears for looseness, and so forth. If you can't find an obvious source of the metal, then change the torque converter! If the converter came apart, there will be metal EVERYWHERE inside (in every passage, every bore and in every crevice). The fluid from converter goes to the transmission cooler, then as lube for all parts inside of transmission. There is nothing to filter the metal shavings out after fluid leaves the converter

Take the governor off (behind the tailhousing. You don't have to mess with the four bolts with lock tab. The removal of snap rings and taking out the pin, it should slide off. Those weights should slide inside of their bores with little effort.

When converter is in place, it should be about 1/2" (13 mm) in above picture. You will need to rotate the converter (a lot) while pushing on it (not hard). You should feel three distinct clunks as the three items line up. Make sure the front pump seal is well lubricated with ATF before inserting the converter.

Before transmission removal, I like to take a bit of spray paint (sharpie, or whatever) and mark one of the flex plate lugs like this:

How or what color doesn't matter. The four torque converter bolts will only all go in, in one manor. If you have two (or three) that line up, but not the forth, you have to stop, remove all bolts, rotate and try again (a big pain in the ____). A person could remove the flexplate, but that is also additional labor.

Note: your converter WILL NOT have a drain plug. Your converter might have a "V" stamped in it (in place of the drain plug) - but sometimes that mark is not present, either.

Hopefully you found a detailed service manual for this transmission.

BudW