This post is about the different alternators used on FMJ's. The next post (same thread) will be on what is needed to retrofit another alternator onto your FMJ.

Before I get into interchangeability, I wanted to touch on five ways to get any alternator to produce more electricity:

1) repair (or replace) one that is malfunctioning.

2) Increase the amount of wiring in the rotor (the part that spins).

3) Increase the amount of voltage being applied to the rotor.

4) Increase the amount of wiring in the stator (the stationary windings).

And/or

5) Increase the rotational speed of the alternator.

Item 1 applies a lot more often than not. It would surprise you.

For most cases, item 3 is kinda limited to 12 volts. If a person "could" apply power to the field windings (the rotor) to 24 volts, you can effectively double the output amperage of any alternator.

Item 5 has some limitations. That would be the “safe” speed or maximum rotational speed before things come apart by centrifugal force (ie: hand grenade). On the Round or Square-back, Chrysler set that speed at 7,000 engine RPM – so pulley sizes used are based off of that speed.

What I don't understand is why the pulley sizes are the same for a 340 (which could reach 7k RPM) and a 318 2-bbl which struggles to get past 4k RPM. The problem with changing pulley size, is just that – not a whole lot of options to change pulley sizes. If a person could increase the alternator speed by say 50%, that would correct (but not eliminate) a lot of “dim lights at idle” concern – but if you have a high RPM engine, you need to also keep that in mind as well.

I have seen a few if the older Chrysler alternators that have came apart – but that also typically ends with a electrical fire – and that doesn't end well for your ride. Trying to stop the car immediately, then disconnecting the battery, then putting out the existing fire quickly, is a very hard thing to do, which HAS TO BE DONE before or you are face-face to one very expensive bonfire. The cars I have worked on – there was no question that alternator over-speed was the cause of failure, or in other terms, the cause of the "expensive bonfire".

The newer design alternators are designed to operate with a higher RPM ceiling – which is part of reason why they work better at low engine RPM.

You can not have “too much of an output” alternator. The vehicle will only use what it needs. In most cases, even a 41-amp alternator only puts out a fraction of what needs when cruising, BUT when at idle which then it is at 100% output (giving the RPM at the time). That said, many of today's cars, the stereo system, electric cooling fans, headed back glass, etc., you need a whole lot more than 41-amp, so for some, a 100-amp might be the bare minimum.

To control the alternator output, Chrysler controls the amount of voltage going to the field windings (to rotor).

Chrysler mostly has used external voltage regulators, mainly to control the amount of voltage for battery charging, based off of the external temperature. The amount of voltage to charge a battery is several volts difference when outside (or underhood) temperature is -20' F (-29 C) which ranges between 14.9 to 15.9 volts, or at 140' F (60 C) which is below 13.6 volts. Newer Chrysler's have a temperature sensor (under and touching the battery) to better adjust the output voltage. This is one reason I like to retain the external voltage regulator.

The numbers used in this paragraph is from my '77 FSM and this is performed using a “factory design voltage regulator”.

I can understand why people would rather go with simplicity with the single wire designs (which use alternator temp instead of firewall temp) – and in their cases (garage kept vehicles seeing limited temperature ranges) – then this might be the best option for them. When these cars were built and sold, the factory design would have been the best version for the masses.

One item that is way often overlooked when increasing the alternator output is you also need to increase the size of the cable going to the battery. The factory size cable is only barely adequate. I have also seen, way too many times, where the battery cable melted. If that happens, you only have a very short time to disconnect the battery before (again) you have a very expensive bonfire. For me, this is hard to tell if someone has increased alternator size without wiring upgrade for you just don't know. Personally, if you are planing on spending some money for your ride, you might want to just upgrade the size of the cable from alternator to battery, just so you don't ever have to experience that “expensive bonfire” feeling.

My guess is copper must have been hard to get, or was expensive back in the '60's to '80's . . . maybe.

Most of the alternators made from '64-87 look like this, on the front:

The Chrysler alternators from '64-71 are refereed to the “round-back” design:

The “round-back” has a single field wire ('64-69) and dual field wire ('70 and newer). It is easy to use a dual field wire alternator (or even a “square-back” alternator – which are all duel field wire) by taking a piece of wire, to either field wire, to ground.

The Yellow arrow, above) shows one of the field wires, which in this case is grounded by the brush holder screw,

The '72-87 alternators are referred as “square-back” - but are more rectangular in design. Either way, a much better design and very easy to repair (over the round-backs).

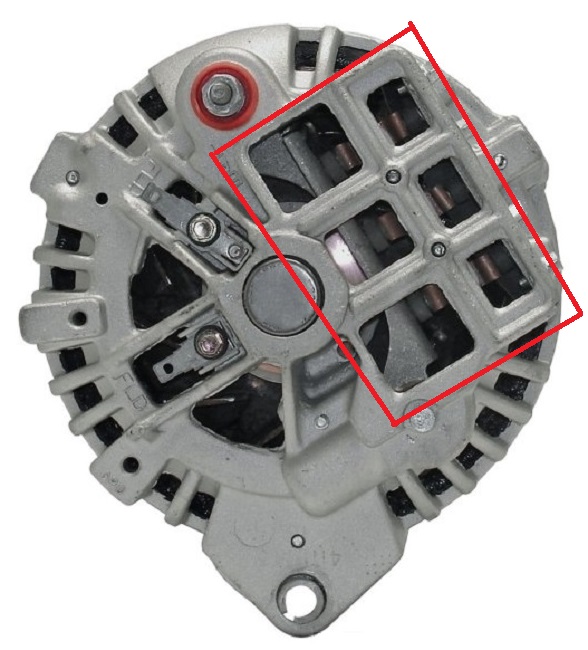

In 1978 (a mid-year change) the square-back alternators went metric. Some internal parts are interchangeable and other items are not. The easy way to tell them apart is the stator (the black steel part between aluminum case halves). The early square-backs have a wide (viewable) stator and metric version has a narrow (viewable) stator. As a unit, they still interchange.

Most vehicles with A/C use the double-belt alternator pulley and most cars without without A/C used a single belt pulley. The double-belt pulley will work in either case (A/C or no A/C) – so if your vehicle currently has the factory installed A/C compressor removed and you have intention of re-installing A/C sometime down the road, be sure to use a double-belt pulley just so there is one less thing to change later on.

You can change pulleys with the proper tools, but it is difficult to install an alternator pulley on the car without damaging the bearings. You really need to take the (any design) alternator apart and use a press to install (or change) the pulley, to prevent any damage.

Factory installed (square-back) alternator sizes (a = Amps):

'76-'78 (mid-year change to Metric – but size choices are the same)

41a, 50a, 60a and 65a

'79-'81

60a and 65a

'82-'87

60a and 78a

'87 was the last year of the square-back alternators (and the huge starters)

'88-'89

90a (Denso or newer Chrysler design) and 120a (new Chrysler design_

Note: my '77 (no-A/C) wagon was built with a 41a alternator. It failed a couple years back and has sense been replaced with an 78a alternator. I haven't upgraded the wiring in that car … yet, because there is not much electrical items on the car, currently (very few options/base model). Before I go fuel injection and electrical cooling fans, the wiring and alternator will be upgraded.

My '86 Fifth Ave has a factory installed 78a alternator – for that vehicle has every electrical option for that car (except for 100a alternator). Before it gets fuel injection and electrical cooling fans, it will also get upgraded.

Note: the alternator brackets (and sometimes A/C brackets) are completely different between these three alternator options (used on FMJ's).

- Square-back ('72-'87)

- 100a (or 114a) – which is a huge (and heavy) assembly ('75-'87).

- Denso ('88 and newer) and Chrysler design ('88 and newer) aka: plastic-back

If you are considering changing the alternator “type” you will need to either get the complete bracket setup or perform major modifications to existing bracket setup.

The 100a (or 114a) alternator:

I don't think I have ever replaced a defective 100a alternator. That said, I have dropped a few (um, did I say that out loud?) which damaged it beyond reuse. It is built like a tank (and might even be used on one...maybe).

A tip: If you have back problems = DO NOT REPLACE one, for it is heavy. They make for a great door stop and/or (above ground) tent stake.

Adapting a Denso (short for Nippendenso) will be easier but not exactly a direct bolt-in. At the end of Model Year '87 Chrysler quit using the "square-back" 60-65 amp alternator and went to a new design ('88 and newer) Chrysler (90 or 120) amp and Denso alternator (90a)- as well as the small design Denso mini-starters (also in '88).

For the most part, all '88/89 (M-body, pickups and vans) came with either 90a Denso or optional 120a Chrysler – but due to a lack of supply, some 90a Chrysler alternators were used (which use the 120a brackets).

Denso 90a (note: it is very easy to get an higher amperage Denso that will bolt right in place of your existing Denso).

(Newer) Chrysler 120a (or 90a)

Both 90a and 120a versions have a black plastic back on them – so easy to tell it apart,

For small blocks There is a total of three different alternator bracket setups (the square-back Chrysler, the huge (older) 100/114a Chrysler and the new 90/120a Chrysler/Denso.

The '88 and newer alternator bracket set is NICE sense it has an bolt that can be used to tighten alternator belt, where as the '87 and older is, um, well, more difficult to tighten the drive belt.

The built-in tightening bolt, by itself, is worth the cost to upgrade to the Denso alternator. Then having the smaller and lighter alternator is only more benefits.

None of /6's got the Denso or the newer 90/120a Chrysler alternators.

The Denso's come in both externally regulated and internally regulated variants but all of the Factory design alternators are externally regulated.

Personally I prefer the externally regulated versions sense do a better job with voltage between the temperature ranges - but this is debate worthy of another thread

If wanting to upgrade your alternator output and currently have a square-back - I would recommend looking for a aftermarket high output version of the square-back - and upgrade the wiring (for the increased amperage output). This is the simplest option and will require the fewest changes. Trying to find a '88 to '92 (non-Magnum) small block bracket set, intact, is not easy and a bit of work to replace existing brackets, as well (IMO) - but with a good donor car (or pickup), makes it a lot easier.

BudW

Before I get into interchangeability, I wanted to touch on five ways to get any alternator to produce more electricity:

1) repair (or replace) one that is malfunctioning.

2) Increase the amount of wiring in the rotor (the part that spins).

3) Increase the amount of voltage being applied to the rotor.

4) Increase the amount of wiring in the stator (the stationary windings).

And/or

5) Increase the rotational speed of the alternator.

Item 1 applies a lot more often than not. It would surprise you.

For most cases, item 3 is kinda limited to 12 volts. If a person "could" apply power to the field windings (the rotor) to 24 volts, you can effectively double the output amperage of any alternator.

Item 5 has some limitations. That would be the “safe” speed or maximum rotational speed before things come apart by centrifugal force (ie: hand grenade). On the Round or Square-back, Chrysler set that speed at 7,000 engine RPM – so pulley sizes used are based off of that speed.

What I don't understand is why the pulley sizes are the same for a 340 (which could reach 7k RPM) and a 318 2-bbl which struggles to get past 4k RPM. The problem with changing pulley size, is just that – not a whole lot of options to change pulley sizes. If a person could increase the alternator speed by say 50%, that would correct (but not eliminate) a lot of “dim lights at idle” concern – but if you have a high RPM engine, you need to also keep that in mind as well.

I have seen a few if the older Chrysler alternators that have came apart – but that also typically ends with a electrical fire – and that doesn't end well for your ride. Trying to stop the car immediately, then disconnecting the battery, then putting out the existing fire quickly, is a very hard thing to do, which HAS TO BE DONE before or you are face-face to one very expensive bonfire. The cars I have worked on – there was no question that alternator over-speed was the cause of failure, or in other terms, the cause of the "expensive bonfire".

The newer design alternators are designed to operate with a higher RPM ceiling – which is part of reason why they work better at low engine RPM.

You can not have “too much of an output” alternator. The vehicle will only use what it needs. In most cases, even a 41-amp alternator only puts out a fraction of what needs when cruising, BUT when at idle which then it is at 100% output (giving the RPM at the time). That said, many of today's cars, the stereo system, electric cooling fans, headed back glass, etc., you need a whole lot more than 41-amp, so for some, a 100-amp might be the bare minimum.

To control the alternator output, Chrysler controls the amount of voltage going to the field windings (to rotor).

Chrysler mostly has used external voltage regulators, mainly to control the amount of voltage for battery charging, based off of the external temperature. The amount of voltage to charge a battery is several volts difference when outside (or underhood) temperature is -20' F (-29 C) which ranges between 14.9 to 15.9 volts, or at 140' F (60 C) which is below 13.6 volts. Newer Chrysler's have a temperature sensor (under and touching the battery) to better adjust the output voltage. This is one reason I like to retain the external voltage regulator.

The numbers used in this paragraph is from my '77 FSM and this is performed using a “factory design voltage regulator”.

I can understand why people would rather go with simplicity with the single wire designs (which use alternator temp instead of firewall temp) – and in their cases (garage kept vehicles seeing limited temperature ranges) – then this might be the best option for them. When these cars were built and sold, the factory design would have been the best version for the masses.

One item that is way often overlooked when increasing the alternator output is you also need to increase the size of the cable going to the battery. The factory size cable is only barely adequate. I have also seen, way too many times, where the battery cable melted. If that happens, you only have a very short time to disconnect the battery before (again) you have a very expensive bonfire. For me, this is hard to tell if someone has increased alternator size without wiring upgrade for you just don't know. Personally, if you are planing on spending some money for your ride, you might want to just upgrade the size of the cable from alternator to battery, just so you don't ever have to experience that “expensive bonfire” feeling.

My guess is copper must have been hard to get, or was expensive back in the '60's to '80's . . . maybe.

Most of the alternators made from '64-87 look like this, on the front:

The Chrysler alternators from '64-71 are refereed to the “round-back” design:

The “round-back” has a single field wire ('64-69) and dual field wire ('70 and newer). It is easy to use a dual field wire alternator (or even a “square-back” alternator – which are all duel field wire) by taking a piece of wire, to either field wire, to ground.

The Yellow arrow, above) shows one of the field wires, which in this case is grounded by the brush holder screw,

The '72-87 alternators are referred as “square-back” - but are more rectangular in design. Either way, a much better design and very easy to repair (over the round-backs).

In 1978 (a mid-year change) the square-back alternators went metric. Some internal parts are interchangeable and other items are not. The easy way to tell them apart is the stator (the black steel part between aluminum case halves). The early square-backs have a wide (viewable) stator and metric version has a narrow (viewable) stator. As a unit, they still interchange.

Most vehicles with A/C use the double-belt alternator pulley and most cars without without A/C used a single belt pulley. The double-belt pulley will work in either case (A/C or no A/C) – so if your vehicle currently has the factory installed A/C compressor removed and you have intention of re-installing A/C sometime down the road, be sure to use a double-belt pulley just so there is one less thing to change later on.

You can change pulleys with the proper tools, but it is difficult to install an alternator pulley on the car without damaging the bearings. You really need to take the (any design) alternator apart and use a press to install (or change) the pulley, to prevent any damage.

Factory installed (square-back) alternator sizes (a = Amps):

'76-'78 (mid-year change to Metric – but size choices are the same)

41a, 50a, 60a and 65a

'79-'81

60a and 65a

'82-'87

60a and 78a

'87 was the last year of the square-back alternators (and the huge starters)

'88-'89

90a (Denso or newer Chrysler design) and 120a (new Chrysler design_

Note: my '77 (no-A/C) wagon was built with a 41a alternator. It failed a couple years back and has sense been replaced with an 78a alternator. I haven't upgraded the wiring in that car … yet, because there is not much electrical items on the car, currently (very few options/base model). Before I go fuel injection and electrical cooling fans, the wiring and alternator will be upgraded.

My '86 Fifth Ave has a factory installed 78a alternator – for that vehicle has every electrical option for that car (except for 100a alternator). Before it gets fuel injection and electrical cooling fans, it will also get upgraded.

Note: the alternator brackets (and sometimes A/C brackets) are completely different between these three alternator options (used on FMJ's).

- Square-back ('72-'87)

- 100a (or 114a) – which is a huge (and heavy) assembly ('75-'87).

- Denso ('88 and newer) and Chrysler design ('88 and newer) aka: plastic-back

If you are considering changing the alternator “type” you will need to either get the complete bracket setup or perform major modifications to existing bracket setup.

The 100a (or 114a) alternator:

I don't think I have ever replaced a defective 100a alternator. That said, I have dropped a few (um, did I say that out loud?) which damaged it beyond reuse. It is built like a tank (and might even be used on one...maybe).

A tip: If you have back problems = DO NOT REPLACE one, for it is heavy. They make for a great door stop and/or (above ground) tent stake.

Adapting a Denso (short for Nippendenso) will be easier but not exactly a direct bolt-in. At the end of Model Year '87 Chrysler quit using the "square-back" 60-65 amp alternator and went to a new design ('88 and newer) Chrysler (90 or 120) amp and Denso alternator (90a)- as well as the small design Denso mini-starters (also in '88).

For the most part, all '88/89 (M-body, pickups and vans) came with either 90a Denso or optional 120a Chrysler – but due to a lack of supply, some 90a Chrysler alternators were used (which use the 120a brackets).

Denso 90a (note: it is very easy to get an higher amperage Denso that will bolt right in place of your existing Denso).

(Newer) Chrysler 120a (or 90a)

Both 90a and 120a versions have a black plastic back on them – so easy to tell it apart,

For small blocks There is a total of three different alternator bracket setups (the square-back Chrysler, the huge (older) 100/114a Chrysler and the new 90/120a Chrysler/Denso.

The '88 and newer alternator bracket set is NICE sense it has an bolt that can be used to tighten alternator belt, where as the '87 and older is, um, well, more difficult to tighten the drive belt.

The built-in tightening bolt, by itself, is worth the cost to upgrade to the Denso alternator. Then having the smaller and lighter alternator is only more benefits.

None of /6's got the Denso or the newer 90/120a Chrysler alternators.

The Denso's come in both externally regulated and internally regulated variants but all of the Factory design alternators are externally regulated.

Personally I prefer the externally regulated versions sense do a better job with voltage between the temperature ranges - but this is debate worthy of another thread

If wanting to upgrade your alternator output and currently have a square-back - I would recommend looking for a aftermarket high output version of the square-back - and upgrade the wiring (for the increased amperage output). This is the simplest option and will require the fewest changes. Trying to find a '88 to '92 (non-Magnum) small block bracket set, intact, is not easy and a bit of work to replace existing brackets, as well (IMO) - but with a good donor car (or pickup), makes it a lot easier.

BudW