1337m4723

Well-Known Member

Hi Guys,

I am back again needing some answers.

My Super Six has some issues containing the carburetor and the vacuum system.

My first question is if I am thinking correctly: when the engine is cold and I am driving, it often dies recently.

I could recreate the problem yesterday, but only when it's cold:

- I hold the throttle as if I were driving steadily.

- Then I take off the gas as if I have to stop at an intersection.

- Then accelerate to start driving again. --> The engine dies and sounds like it has choked/hiccupped.

- When the engine warmed up, I could treat it with different throttle positions in a quick change and it did not die. Even when using the brakes and giving it a lot of throttle ind R or D.

My Idea: the carburetor throttle bearing is worn. When heated, the bearing fits again and the throttle function is back to normal.

Is this plausible? I am not a learned mechanic, so maybe this question is nonsense... But maybe you can understand what I am thinking about.

My second question is: I think the vacuum system has some issues. Idling is not really nice like the engine does not run "round".

I was searching for affordable spare-parts.

Do you know where vacuum parts are available? I don't necessarily need NOS parts. I would be happy with remanufactured Asian products or something similar.

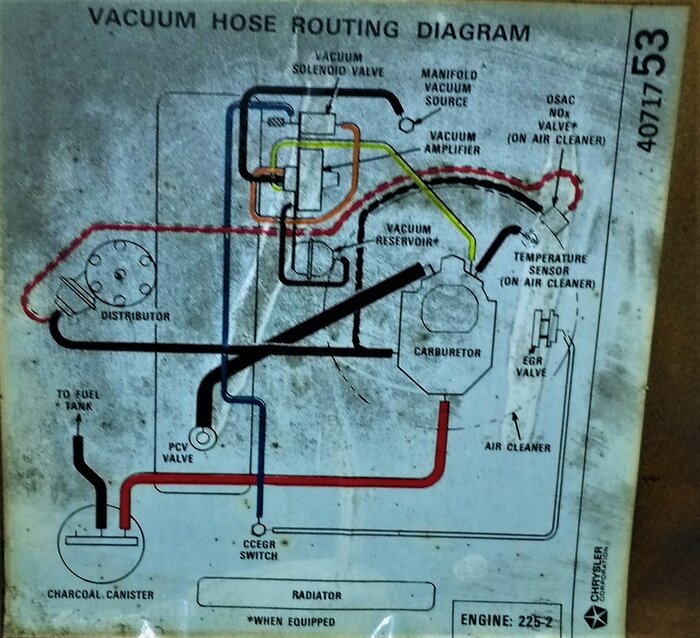

- I blieve the vacuum solenoid valve is leaking. Is there a spare part available?

- I'd like to replace some vacuum-hoses...(my engine still has all original hoses I guess.)

- Is there a spare part for the Vacuum amplifier? (I don't know if this is really necessary...)

Maybe you can give me a hint if there are shops for those parts.. Rockauto has many parts, but not everything.

Best greetings from hanover (Germany)

Matze

I am back again needing some answers.

My Super Six has some issues containing the carburetor and the vacuum system.

My first question is if I am thinking correctly: when the engine is cold and I am driving, it often dies recently.

I could recreate the problem yesterday, but only when it's cold:

- I hold the throttle as if I were driving steadily.

- Then I take off the gas as if I have to stop at an intersection.

- Then accelerate to start driving again. --> The engine dies and sounds like it has choked/hiccupped.

- When the engine warmed up, I could treat it with different throttle positions in a quick change and it did not die. Even when using the brakes and giving it a lot of throttle ind R or D.

My Idea: the carburetor throttle bearing is worn. When heated, the bearing fits again and the throttle function is back to normal.

Is this plausible? I am not a learned mechanic, so maybe this question is nonsense... But maybe you can understand what I am thinking about.

My second question is: I think the vacuum system has some issues. Idling is not really nice like the engine does not run "round".

I was searching for affordable spare-parts.

Do you know where vacuum parts are available? I don't necessarily need NOS parts. I would be happy with remanufactured Asian products or something similar.

- I blieve the vacuum solenoid valve is leaking. Is there a spare part available?

- I'd like to replace some vacuum-hoses...(my engine still has all original hoses I guess.)

- Is there a spare part for the Vacuum amplifier? (I don't know if this is really necessary...)

Maybe you can give me a hint if there are shops for those parts.. Rockauto has many parts, but not everything.

Best greetings from hanover (Germany)

Matze