You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Random Pics

- Thread starter Jack Meoff

- Start date

Aspen500

Well-Known Member

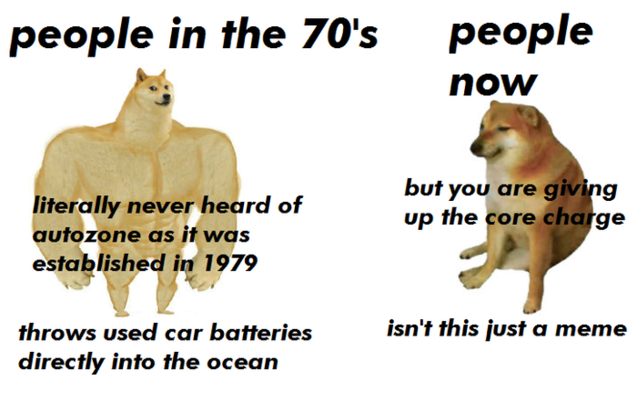

I went to an Autozone here once. Just once......

GregG48213

Well-Known Member

If they can't get migrants to bus tables, it's unlikely they'll find anybody to clean up horseshit.horse drawn

AMC Diplomat

Well-Known Member

Maybe restaurants could find help if people's only other option was to shovel shit. I think the Amish are right about technology. It ruins society at a certain point. People would rather sell pics of their butthole on the internet than work an honest job.If they can't get migrants to bus tables, it's unlikely they'll find anybody to clean up horseshit.

Can still get land in Amish/Mennonite country for a reasonable price. Was just watching a video about a 26 year old guy, grew up in a typical household in Kentucky but, decided it wasn’t for him. Lives in Amish/Mennonite community now, has a shack on 12 acres in a valley with a clean running creek, shoes horses for money, works his land and grows his own food, spends about $140 a month on fruits, salt and a phone bill he splits with his, Amish neighbor for business.

Can still do it if it’s for you. Who knows how long it will even be an option as a way of life. The world is in a drastic state of change.

Can still do it if it’s for you. Who knows how long it will even be an option as a way of life. The world is in a drastic state of change.

Aspen500

Well-Known Member

I make good money doing that. I'm of course kidding! Actually it's my female other half that does. Her website is NOT BEING SERIOUS.com, lol.People would rather sell pics of their butthole on the internet than work an honest job.

AMC Diplomat

Well-Known Member

Can still get land in Amish/Mennonite country for a reasonable price. Was just watching a video about a 26 year old guy, grew up in a typical household in Kentucky but, decided it wasn’t for him. Lives in Amish/Mennonite community now, has a shack on 12 acres in a valley with a clean running creek, shoes horses for money, works his land and grows his own food, spends about $140 a month on fruits, salt and a phone bill he splits with his, Amish neighbor for business.

Can still do it if it’s for you. Who knows how long it will even be an option as a way of life. The world is in a drastic state of change.

Funny, I saw that on YouTube, too. Poor guy doesn't even have a girlfriend and seems a little off. Doesn't even have a well, he gets his water from a creek. He's about 2 steps removed from camping. I get it, but I'd need a well and shoes

AMC Diplomat

Well-Known Member

Stack pallets, lift pallets with forklift and pin the motor to the pallets, unbolt motor, lower down…unfortunately, this is an “easier out than in”, situation. Getting the new motor to line up and bolt up will be a pretty good challenge tomorrow morning.

AMC Diplomat

Well-Known Member

How often do these things fail?Stack pallets, lift pallets with forklift and pin the motor to the pallets, unbolt motor, lower down…unfortunately, this is an “easier out than in”, situation. Getting the new motor to line up and bolt up will be a pretty good challenge tomorrow morning.

View attachment 50666

Aspen500

Well-Known Member

Should be easy to line the new motor up. Can't weigh more than a few hundred pounds. Just muscle it into place, lol.

Most of the motors for the mills have been hanging from the ceiling longer than I’ve been alive. These old Sterling motors are pretty beefy. The Dodge gear reduction box that the motor drives, get rebuilt every 7-10 years or so, depending on when the shaft seals go out and start leaking oil.How often do these things fail?

It’s not too bad. Put some plate metal onto the skid, put motor down onto skid. Give me something to slide it around on when I lift it up. I can only take the lift straight up and down, have a gear box on the left and a water line to the right so, I can’t particularly use side shift/tilt or anything to help get into a better position once I’m raising up under the mounting plate.Should be easy to line the new motor up. Can't weigh more than a few hundred pounds. Just muscle it into place, lol.

AMC Diplomat

Well-Known Member

I'd be drilling a hole in the floor above, put a gantry or some kind of winch above the hole, drop a line down, and lifting it in place through the floor aboveIt’s not too bad. Put some plate metal onto the skid, put motor down onto skid. Give me something to slide it around on when I lift it up. I can only take the lift straight up and down, have a gear box on the left and a water line to the right so, I can’t particularly use side shift/tilt or anything to help get into a better position once I’m raising up under the mounting plate.

I don’t think the owner would appreciate cutting through the joists and support beams that hold up the office floor because, that’s what the motor is hanging from. 2 4x10s bolted to the joists and support beams for the office floor directly above on the 2nd floor. It’s an idea though.I'd be drilling a hole in the floor above, put a gantry or some kind of winch above the hole, drop a line down, and lifting it in place through the floor above

AMC Diplomat

Well-Known Member

I don’t think the owner would appreciate cutting through the joists and support beams that hold up the office floor because, that’s what the motor is hanging from. 2 4x10s bolted to the joists and support beams for the office floor directly above on the 2nd floor. It’s an idea though.

Just a little hole, they'll never notice!

Imma take a picture of the motor next to my hand tomorrow, lol it’s an idea. It’s a 25hp motor, these mills hold about 2k lbs of leather and another 5K lbs of water when a full load is running.

Interestingly, to some, there’s not really anyone left in the world who makes these old wooden leather mills. There used to be a guy in, Milwaukee who’s retired, there’s an old gentleman in, Italy who is still building them but also, in his final years of work. We have an old Polish gentleman who can rebuild them but, he retires at the end of the year.

The modern molded polypropylene mills just don’t deliver the same quality finish as these wooden mills. These have wooden clubs secured inside them that beat the leather allow the water/dye/oil/wax/ect…to really penetrate into the hides. The modern mills are plastic injection molded and instead of clubs, use shelfs/paddles and they have way to much surface area. So, as the mill rotates the leather ends up falling in stacks onto the paddles/shelves and stick to one another and you don’t get the same penetration and finish quality at the end of a run…interestingly, we do specifically use hand made wooden paddle mills in our pickling process.

Paddle mill vs color mill

Color mill. For a size comparison next to a couple men.

We have three different size mills. The color mills are the mid size. Large are the Chrome mills where we make our blues. The stuffing/dry mills are the small mills of the lot.

We have three different size mills. The color mills are the mid size. Large are the Chrome mills where we make our blues. The stuffing/dry mills are the small mills of the lot.