Bruceynz

Well-Known Member

Hi Guys,

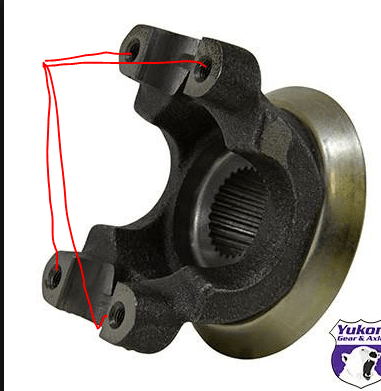

Does anyone know the torque settings for the tiny we bolts that hold for the saddles that go over the cross on the rear end, there are 2 caps and 4 bolts. Where I have tried to draw the red lines.

Thanks

Bruce

Does anyone know the torque settings for the tiny we bolts that hold for the saddles that go over the cross on the rear end, there are 2 caps and 4 bolts. Where I have tried to draw the red lines.

Thanks

Bruce