Bruceynz

Well-Known Member

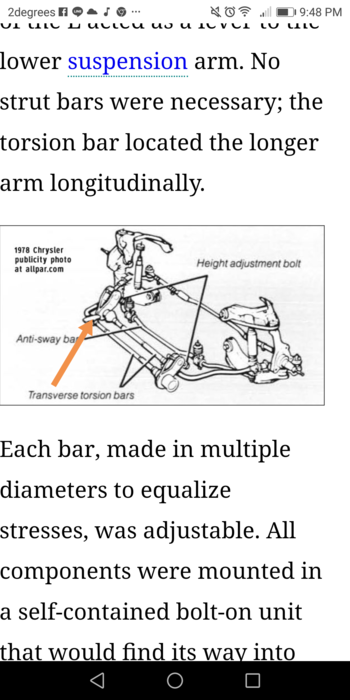

Ok I need to replace this bush, see orange arrow, what's best way to do it? Seems a lot of weight there on that part, had bolts undone and could not separate bracket.

Yes, they are spot welded together. Good luck getting them apart without damaging one side or the other. I`m pretty sure I may have a couple good used ones and maybe one NOS kit but I would have to check.

I think they're spot welded basically for the assembly line. They don't HAVE to be welded, the bolts hold it together when installed.

I second the using poly bushings that are split. I originally tried to use stock rubber replacements. Tried everything and never got the bushing more than a few inches onto the bar. Boiled the bushings to soften them up, tried every form of lubricant know to man and beast, even went so far as to try animal birthing agent (about the slipperiest stuff I've ever touched) and no luck.

I just cut the bloody thing off with angle grinder, drill the welds out and might weld the thing together again, no mucking around.

Nice detective work

Just leave everything a lil loose............

The stock system works because the rubber has a lot of compliance.Hi AJ,

But that is an issue with that suspension design?

Thanks

Bruce