I wish he would put the year/make/model on his signature . . .

FMJ’s have two different styles of bowl vents.

Mechanical (non Lean Burn/ESC) or electrical (with Lean Burn/ESC).

A third method would be to use older equipment that doesn’t have either.

I can’t access his pictures or video’s he posted on March 29 or 30 on my work computer (will need to go home, first).

For some reason videos are not allowed at work as well as some formats of pictures.

One of the problems of working 11am to 8pm shift . . .

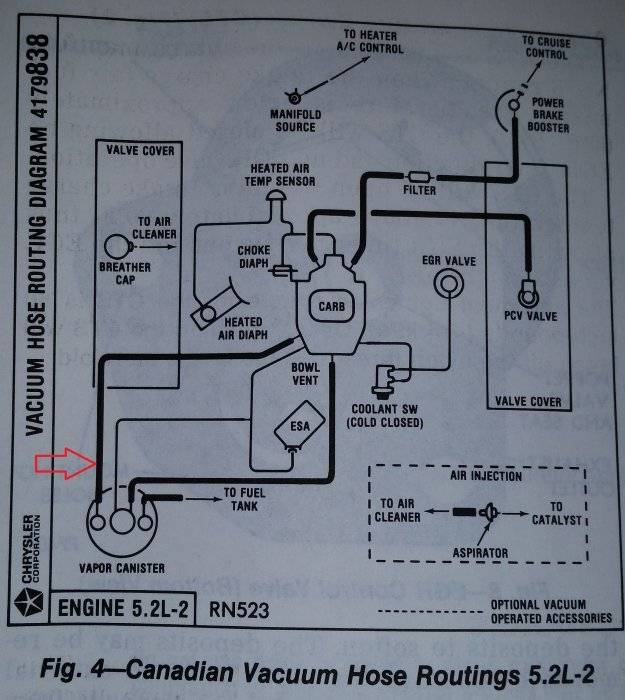

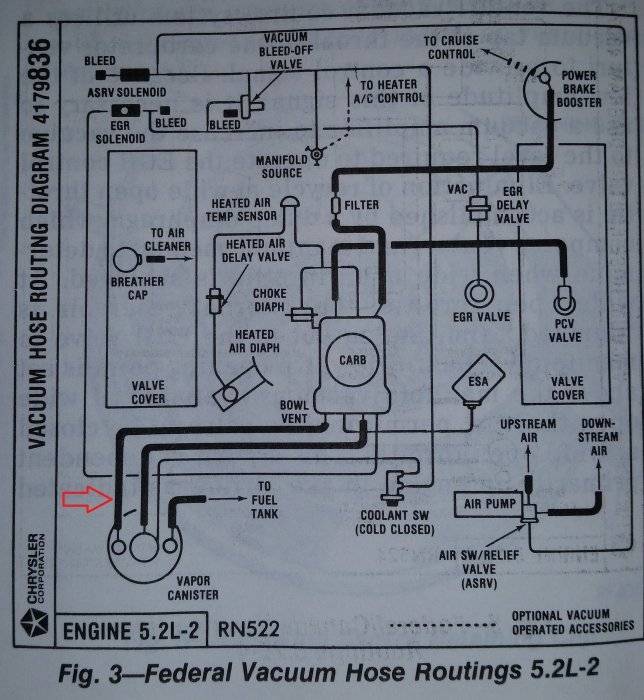

To help, these are from my ’86 service manual and all versions have Lean Burn (ESC/ESA).

Both diagrams show large hoes going to the charcoal canister. The red arrows are the large hose.

On the charcoal canister there is a smallish hose coming from base of carburetor which sucks the vapor from the canister. The other hose is what turns the other small hose functionality on.

Personally, I think the charcoal canister/fuel vapor is a good system to keep in place.

That said, if you are missing parts – it is not worth time or $ to locate missing parts – unless you live in a state that requires it.

BudW

FMJ’s have two different styles of bowl vents.

Mechanical (non Lean Burn/ESC) or electrical (with Lean Burn/ESC).

A third method would be to use older equipment that doesn’t have either.

I can’t access his pictures or video’s he posted on March 29 or 30 on my work computer (will need to go home, first).

For some reason videos are not allowed at work as well as some formats of pictures.

One of the problems of working 11am to 8pm shift . . .

To help, these are from my ’86 service manual and all versions have Lean Burn (ESC/ESA).

Both diagrams show large hoes going to the charcoal canister. The red arrows are the large hose.

On the charcoal canister there is a smallish hose coming from base of carburetor which sucks the vapor from the canister. The other hose is what turns the other small hose functionality on.

Personally, I think the charcoal canister/fuel vapor is a good system to keep in place.

That said, if you are missing parts – it is not worth time or $ to locate missing parts – unless you live in a state that requires it.

BudW