A lot of funny things happen on the assembly line.

The paint markings are mostly used to:

A keep the ring and pinion gear sets together (matched).

B for measurements for correct shim(s) to be installed

C Fasteners are tested to be a correct torque.

D Post-inspection checks or notes.

The part of pinion gear that is closest to the axle center-line is measured to determine the distance of that edge to the axle center-line. Typically one person measures that distance and makes a mark. The next person in line will take a shim and a tool block (that is thickness of the bearing) and then installs it. The next person measures again and if correct, will move to next person to get rear pinion bearing pressed into place or will send that group of parts back to person number one (or to person two, or …).

Post assembly, but before differential is shipped to assembly plant, there will be several inspections with their own paint marks, saying “it is good”.

On the repair side, the same measurements are made when installing a new ring/pinion gear set, but tech will make notes in his head or pen/paper, make the correct calculations and install the correct shim(s). If not making any shortcuts, the tech will retest that measurements before going onto the next step.

I have seen maybe 30 different paint marks at different locations on a differential – back when I was at a dealership.

Now at the assembly plant, some parts can/will run out (strikes, ships sink, someone forgot to order, …) and I have seen them install what they have to keep the line from stopping, even if is a more expensive part.

On the new car purchasing area, this could have been a special order car, or had a trailer towing package installed. Usually the body tag might mention this (sometimes).

I've heard of a couple of Fifth Ave's being used for US senator security that might have gotten an high-end AHB via other means.

I don't think a person will find out what all those markings mean and really, It might not make a difference.

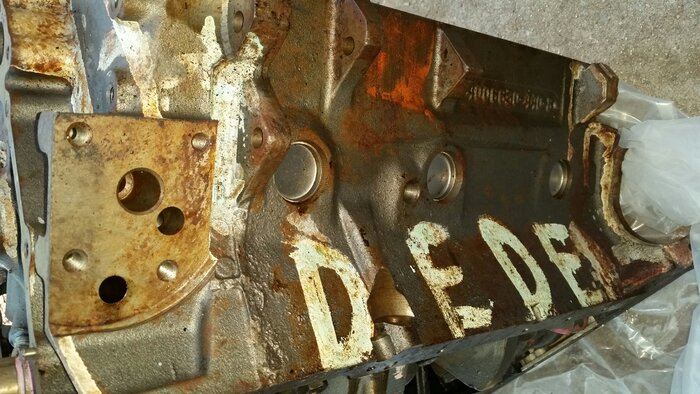

Here are some pictures of a NOS block and there are paint marks in all kinds of areas. I suspect the letters on side of block might be bore size – but honestly, I don't care (not going to look it up). All of these marks came from the factory.

Each bolt/nut has a dab of paint on it (plus at a number of other areas).

Pay no attention to the white arrow.

Yes, the numbers (or paint marks) are important to the workers who build it - but no, they are not important (or useful) after it leaves the assembly plant.

BudW

The paint markings are mostly used to:

A keep the ring and pinion gear sets together (matched).

B for measurements for correct shim(s) to be installed

C Fasteners are tested to be a correct torque.

D Post-inspection checks or notes.

The part of pinion gear that is closest to the axle center-line is measured to determine the distance of that edge to the axle center-line. Typically one person measures that distance and makes a mark. The next person in line will take a shim and a tool block (that is thickness of the bearing) and then installs it. The next person measures again and if correct, will move to next person to get rear pinion bearing pressed into place or will send that group of parts back to person number one (or to person two, or …).

Post assembly, but before differential is shipped to assembly plant, there will be several inspections with their own paint marks, saying “it is good”.

On the repair side, the same measurements are made when installing a new ring/pinion gear set, but tech will make notes in his head or pen/paper, make the correct calculations and install the correct shim(s). If not making any shortcuts, the tech will retest that measurements before going onto the next step.

I have seen maybe 30 different paint marks at different locations on a differential – back when I was at a dealership.

Now at the assembly plant, some parts can/will run out (strikes, ships sink, someone forgot to order, …) and I have seen them install what they have to keep the line from stopping, even if is a more expensive part.

On the new car purchasing area, this could have been a special order car, or had a trailer towing package installed. Usually the body tag might mention this (sometimes).

I've heard of a couple of Fifth Ave's being used for US senator security that might have gotten an high-end AHB via other means.

I don't think a person will find out what all those markings mean and really, It might not make a difference.

Here are some pictures of a NOS block and there are paint marks in all kinds of areas. I suspect the letters on side of block might be bore size – but honestly, I don't care (not going to look it up). All of these marks came from the factory.

Each bolt/nut has a dab of paint on it (plus at a number of other areas).

Pay no attention to the white arrow.

Yes, the numbers (or paint marks) are important to the workers who build it - but no, they are not important (or useful) after it leaves the assembly plant.

BudW