IH8GMandFord

Member

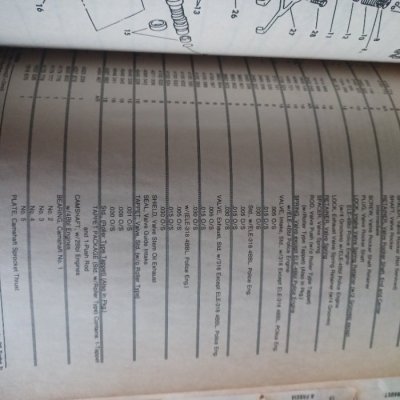

What's up forum! I'm getting ready to work on the 1988 Gran Fury AHB & am considering slapping in a different cam since the front of the motor is torn down to the timing chain cover. It has the factory 318 4bbl. The cam I have is a MP .430"/ .450", 260/260 hydraulic flat tappet I bought 20 years ago. I also have a new Summit double roller chain.

So the question: can I do the cam swap without dropping the oil pan? Will it be a royal PITA to get it to reseal? The radiator, condenser, tranny cooler, and grill are removed w/ all accessories/ brackets.

Thanks for any and all input, as well as advice for the swap. I also have a new AVS2 and the Summit electronic ignition kit.

So the question: can I do the cam swap without dropping the oil pan? Will it be a royal PITA to get it to reseal? The radiator, condenser, tranny cooler, and grill are removed w/ all accessories/ brackets.

Thanks for any and all input, as well as advice for the swap. I also have a new AVS2 and the Summit electronic ignition kit.