You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'83 Mirada street/strip project - my official return to FMJ!

- Thread starter 72Dodge

- Start date

72Dodge

Well-Known Member

I'd be trying to sponge it up and squeeze it back out into the tank!

72Dodge

Well-Known Member

Did a quick test fit of the engine yesterday. Looks like no problem other than the headers are going to be a PITA. QUESTION: Can anyone tell me how much space there is between the balancer (or whatever it's called) and the k-member when using the stock mounts? When I had it where I thought I wanted it, it seemed awful close to the K. Since I'm using a motor plate (against all reason and logic, don't start with me  ), I want to be sure I leave enough room.

), I want to be sure I leave enough room.

So today I lost my safety spotter, so I did some non-engine related work. I took out the carpets and was going to put down my Menard's window flashing heat/sound insulation, but it turned out the factory stuff is perfect, so I just put it back. All the floors were nearly perfect. This is why it would have been a shame to not save this car. Underneath the car is almost as clean (in Texas all it's life). It's a real shame anyone ever messed with this car, if they hadn't, I think it would have been a great survivor.

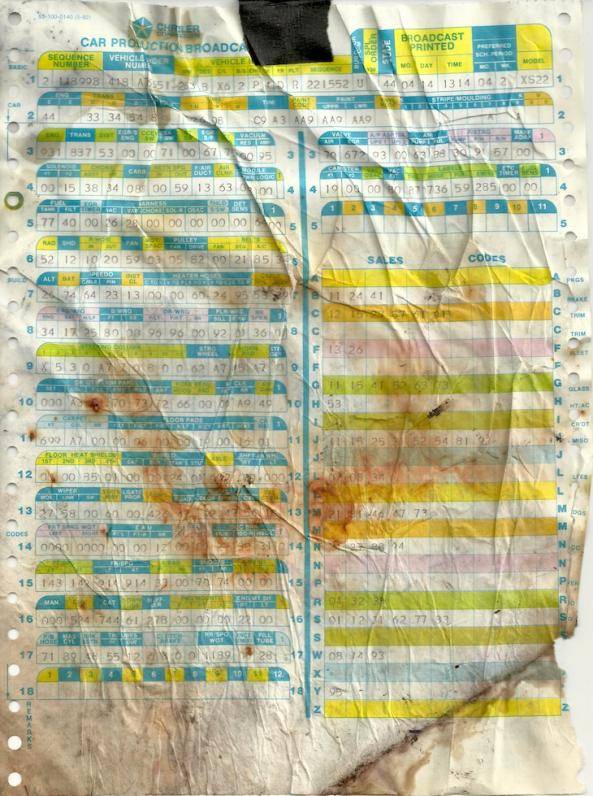

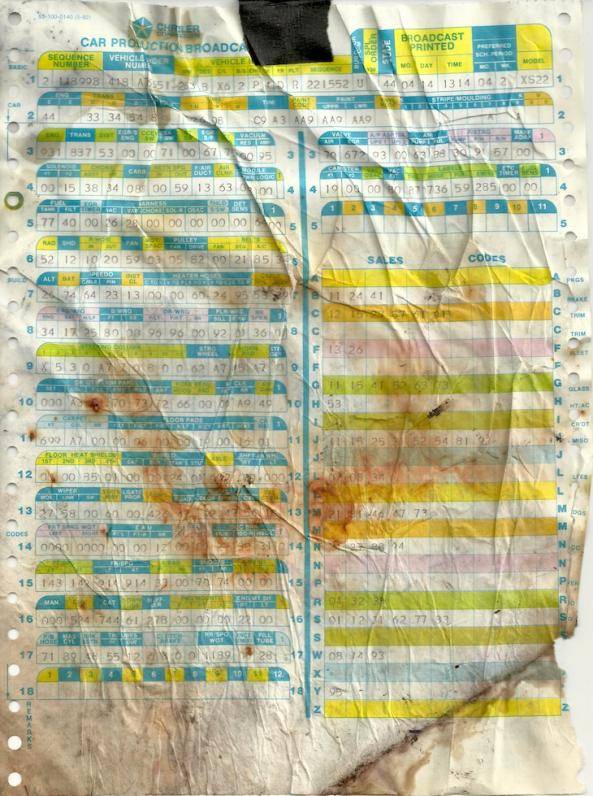

And I found the original (matching) build sheet under the carpet. It doesn't matter, since no one really cares, and I'm not restoring it, but I'm going to decode it for fun anyway.

So today I lost my safety spotter, so I did some non-engine related work. I took out the carpets and was going to put down my Menard's window flashing heat/sound insulation, but it turned out the factory stuff is perfect, so I just put it back. All the floors were nearly perfect. This is why it would have been a shame to not save this car. Underneath the car is almost as clean (in Texas all it's life). It's a real shame anyone ever messed with this car, if they hadn't, I think it would have been a great survivor.

And I found the original (matching) build sheet under the carpet. It doesn't matter, since no one really cares, and I'm not restoring it, but I'm going to decode it for fun anyway.

Last edited:

Are there no provisions for stock mounts? I'm not starting with you about the motor plates, but the engine shouldn't sit perfectly level, nor should it be perfectly centered. You want it offset to the passenger's side like it was from the factory for not only maximum header clearance on that side, but also to keep your drivetrain angles correct. I'll get some measurements off the Imperial once last night's rain dries... yep, she's finally home. :eusa_dance:

72Dodge

Well-Known Member

Lol, no that's fine  Stock mounts were cut off as part of the previous owner's hack job program, and I think all things considered, this is my path of least resistance. Any measurements you can give are great. I have it offset, the trans tunnel ensures that anyway... It's mostly up/down angle that is still a question. Congrats on having the imp home!

Stock mounts were cut off as part of the previous owner's hack job program, and I think all things considered, this is my path of least resistance. Any measurements you can give are great. I have it offset, the trans tunnel ensures that anyway... It's mostly up/down angle that is still a question. Congrats on having the imp home!

Last edited:

The transmission mount should determine fore/aft as well. You should be doing your setup with the trans mount firmly bolted in place. The real concern is going to be in the vertical plane.

I'll get pics of the old pig up a little later. It's nice to have more lawn litter. :icon_biggrin:

I'll get pics of the old pig up a little later. It's nice to have more lawn litter. :icon_biggrin:

72Dodge

Well-Known Member

Yes, I mean the angle, not fore/aft position (stock trans mount is firmly bolted in (thanks again!), which takes care of a lot of it). I'm not describing it well... fore/aft was definitely not the right away to say it. Basically, how close the balancer is to the k. I'm probably being even more overly cautious than I need to be, but I'd rather get it more perfect than less perfect.

Last edited:

72Dodge

Well-Known Member

Wow, I just went back through my last few posts and fixed all the typos (thumb-o's?). Was trying to post on my little tablet instead of a computer. I wasn't making any sense at all!

OK, per the weatherman the wet grass is only gonna get wetter in the next couple of hours, so I decided to just bite the bullet and get this done. With everything still in a running car, this is not an easy thing to accomplish particularly when you're lawnmower is broken. I got under the car and just start jamming the camera in various places, including a couple so tight I had to get the camera into position prior to turning it on, because the extended lens wouldn't clear. :eusa_doh: Anyhow, if you want to PM me your e-mail I can send you a plethora of confusing photos--there's no reference as to which way is up, except that most of them are taken from under the car. I doubt they will help you, but you might find them rather entertaining. :icon_biggrin:

These are the best shots I could get. There's less than an inch between the balancer and the K, and the bottom edge of the pulley is about equal with, if not a bit lower than, the flat part of the K beneath the oil pan. Hopefully, these will help.

Clearest shot I could get:

Different angle, a little further back:

My dog:

These are the best shots I could get. There's less than an inch between the balancer and the K, and the bottom edge of the pulley is about equal with, if not a bit lower than, the flat part of the K beneath the oil pan. Hopefully, these will help.

Clearest shot I could get:

Different angle, a little further back:

My dog:

Jack Meoff

Mopar Maniac

Dog looks like he's having a rough day....

72Dodge

Well-Known Member

Those actually are helpful, thank you. You should get hazard pay for that. I will PM you my email if you want to send more.

Your dog looks like she was imitating one of your positions as you were trying to take pics!

Your dog looks like she was imitating one of your positions as you were trying to take pics!

Jack Meoff

Mopar Maniac

Lmao!!!

72Dodge

Well-Known Member

I feel like I finally accomplished something today. Unfortunately, first thing this morning, I discovered that I do not have a flexplate that will work with my torque converter. I'll order that tonight. If I'd had that, I might have even gotten the engine completely installed today.

So, other than finishing engine setup (TDC, plugs, and so on), I did the final test fit. Once I bolted the engine up to the trans, everything came together. With everything lined up the way I wanted it (almost, more on that below), there's an appropriate distance between the balancer and the K, the headers (a-body Hooker Super Comps) fit with no trouble at all (it was surprisingly easy to fit them, of course, I have the manual steering which helps). The only clearance issue I had was the passenger's side custom mounts that the previous owner welded in, so I'll trim those down, then I can move the engine over to the passenger's side a little more where it should be. Then, no trouble at all.

I even test fit the clutch fan and radiator. Even with the extra plate thickness, it looks like it's all going to fit just fine. That surprised me a bit.

Oh yeah, the one problem I did run across is that I'll have to cut a small hole in the motor plate to use the stock mechanical fuel pump, or use an electric pump. I think the hole will be small enough that it won't cause a problem, but I'll judge that once I get the rest of the plate cut.

As soon as I get that correct flex plate, I'll be on my way to what should be a fairly trouble-free-ish install!

And no, that transmission lying there isn't the one for this car. That's a big block 727... I have five or six random transmissions lying around in the garage. The only place I had for that one was literally between the cars. It's ridiculous.

So, other than finishing engine setup (TDC, plugs, and so on), I did the final test fit. Once I bolted the engine up to the trans, everything came together. With everything lined up the way I wanted it (almost, more on that below), there's an appropriate distance between the balancer and the K, the headers (a-body Hooker Super Comps) fit with no trouble at all (it was surprisingly easy to fit them, of course, I have the manual steering which helps). The only clearance issue I had was the passenger's side custom mounts that the previous owner welded in, so I'll trim those down, then I can move the engine over to the passenger's side a little more where it should be. Then, no trouble at all.

I even test fit the clutch fan and radiator. Even with the extra plate thickness, it looks like it's all going to fit just fine. That surprised me a bit.

Oh yeah, the one problem I did run across is that I'll have to cut a small hole in the motor plate to use the stock mechanical fuel pump, or use an electric pump. I think the hole will be small enough that it won't cause a problem, but I'll judge that once I get the rest of the plate cut.

As soon as I get that correct flex plate, I'll be on my way to what should be a fairly trouble-free-ish install!

And no, that transmission lying there isn't the one for this car. That's a big block 727... I have five or six random transmissions lying around in the garage. The only place I had for that one was literally between the cars. It's ridiculous.

Jack Meoff

Mopar Maniac

Nice! The home stretch approaches..

Holley, Carter, and Edelbrock all make mechanical fuel pumps with "clockable" lower housings that can be turned for clearance issues. Of course, you're looking at a 3-digit pump, so you've kind of got to be committed to the mechanical. On the bright side, they're rebuidable in the event of a failure. The other option is that if the fitting is a threaded one, you can usually find a 45° or 90° male/female adapter that can get you "around the corner" rather than having to drill a hole.

I don't think the hole will cause a worrisome strength issue, but I can certainly see it becoming a pain in the ass for service or maintenance reasons.

I don't think the hole will cause a worrisome strength issue, but I can certainly see it becoming a pain in the ass for service or maintenance reasons.

72Dodge

Well-Known Member

Interesting. I'm definitely not going to commit to a 3-figures mechanical pump because this is a more-or-less temporary solution until I install a fuel cell and electric pump down the road (I had this brand-new stock Carter replacement sitting here, figured I may as well use it for phase 1). Still, I wasn't aware of the clockable ones, so that's an interesting tidbit to stash away. I also didn't know about the adapters, so I'll keep that in mind for final fitment when I decide how I'm going to solve the problem.

Overall though, since this is literally the only problem I discovered (not counting having to hack off the nearly useless custom mount ears), I'm pretty happy.

I'm glad I'm getting the experience with the motor plate setup, actually. It takes installing an engine from the usual quick, no-hassle affair to something of a puzzle. It makes it more interesting, and is good experience and fun for me. That said, I won't forget this, and I'm pretty sure I'll never do it again

Overall though, since this is literally the only problem I discovered (not counting having to hack off the nearly useless custom mount ears), I'm pretty happy.

I'm glad I'm getting the experience with the motor plate setup, actually. It takes installing an engine from the usual quick, no-hassle affair to something of a puzzle. It makes it more interesting, and is good experience and fun for me. That said, I won't forget this, and I'm pretty sure I'll never do it again

72Dodge

Well-Known Member

Oh, I just re-read what you wrote there. It's not just the outlet fitting that will be in the way of the front plate, it's actually the fuel pump housing itself. The widest part of the pump (except maybe where it mounts to the block). It looks like it's going to need a "slot" hole for the housing to fit, then probably another hole right below that for the outlet (or much more likely, I'll use an adapter as you suggested, I can't recall offhand if it's threaded or not). In other words, clocking the lower housing only solves part of the interference issue. I should have foreseen this, but... didn't.

I should have taken a picture, but didn't really have enough hands when I was holding up either the actual plate or my cardboard template.

EDIT: I figured out what you meant by the adapter, so I edited the above to reflect that. It should solve half of the problem, just not the housing.

I should have taken a picture, but didn't really have enough hands when I was holding up either the actual plate or my cardboard template.

EDIT: I figured out what you meant by the adapter, so I edited the above to reflect that. It should solve half of the problem, just not the housing.

Last edited:

Well, try to have more hands in the future. :icon_biggrin:

If you have to make a "slot" for the pump housing, make sure it is round on both ends and has absolutely no sharp corners or edges. That's a pretty decent amount of metal to have to remove, and anything sharp like a corner will create a stress riser where cracks can and will start.

As far as the fitting, what I meant was that if the pump outlet connection is the typical inverted-flare fitting for a hard line, you can find one that's male/female on the needed angle (technically the "45°" would be a 135°) to point your line outlet somewhere that it's not pointing directly at the motor plate. You still may need a hole to clear it, but at least you won't have to try and run a line through it.

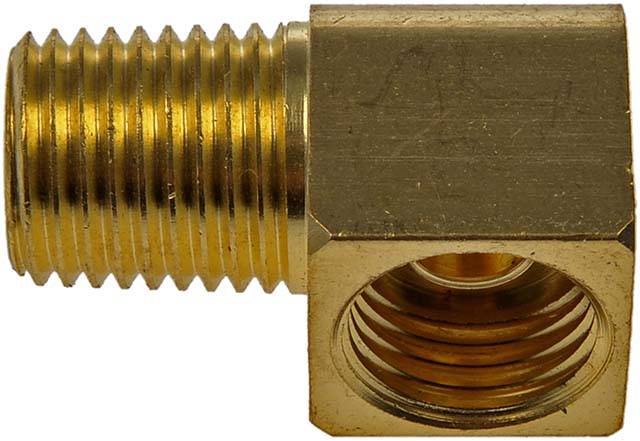

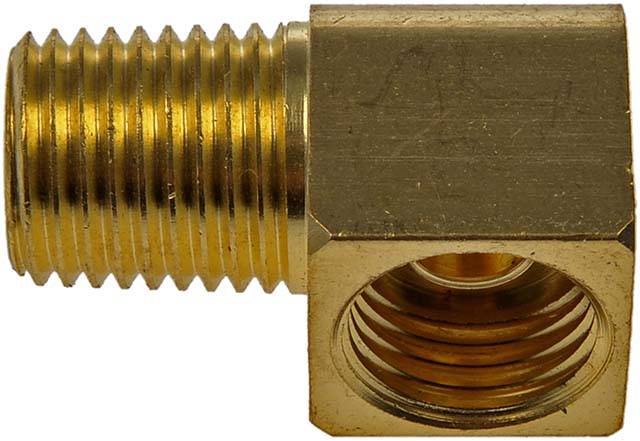

Something like this, which is actually 1/4"NPT to 5/16" hard line, but you get the idea (the fitting you need exists):

If you have to make a "slot" for the pump housing, make sure it is round on both ends and has absolutely no sharp corners or edges. That's a pretty decent amount of metal to have to remove, and anything sharp like a corner will create a stress riser where cracks can and will start.

As far as the fitting, what I meant was that if the pump outlet connection is the typical inverted-flare fitting for a hard line, you can find one that's male/female on the needed angle (technically the "45°" would be a 135°) to point your line outlet somewhere that it's not pointing directly at the motor plate. You still may need a hole to clear it, but at least you won't have to try and run a line through it.

Something like this, which is actually 1/4"NPT to 5/16" hard line, but you get the idea (the fitting you need exists):

72Dodge

Well-Known Member

Yep, got it. I think that will solve that part of the problem. Thanks for the tip on the stress risers.